Introduction

Using a circular saw to cut plywood is a common task in woodworking and DIY projects. Knowing the right techniques, tools, and safety measures can make the process easier and produce cleaner, more precise cuts. This guide will walk you through everything you need to know to cut plywood efficiently and safely.

Read our guide on choosing the best circular saw blades to improve your results when using a circular saw to cut plywood.

Table of Contents

Choosing the Right Circular Saw

When using a circular saw to cut plywood, selecting the right saw is essential for accurate and clean cuts. Circular saws come in two main types: corded and cordless.

- Corded circular saws provide consistent power and are suitable for long or heavy-duty cuts. They are ideal if you are working in one location with access to electricity.

- Cordless circular saws offer more mobility and convenience, especially for outdoor projects or areas without power outlets. However, battery life can limit continuous work.

The blade type is also important. For plywood, use a fine-toothed blade to reduce splintering. The blade size should match the thickness of the plywood you plan to cut. A 7-1/4 inch blade is common and works for most standard plywood sheets.

Adjustable features like blade depth and bevel settings can make cutting easier and more precise. Make sure the saw feels comfortable in your hands and is easy to control, especially when making long cuts.

Selecting the Right Plywood

When using a circular to cut plywood, choosing the correct type of plywood is important for achieving clean and precise cuts. Plywood comes in different grades, thicknesses, and materials, and each affects how easy it is to cut and how smooth the edges will be.

- Thickness: Standard plywood comes in 1/4 inch, 1/2 inch, and 3/4 inch sheets. Thicker plywood is stronger but harder to cut, while thinner sheets are easier to handle but may flex or bend.

- Grade: Plywood is graded from A to D based on surface quality. Higher-grade plywood has fewer knots and defects, making it smoother and less prone to splintering when using a circular saw.

- Type: There are various types of plywood, such as hardwood, softwood, and marine plywood. Hardwood plywood is strong and durable, softwood is lighter, and marine plywood is moisture-resistant, ideal for outdoor projects.

Knowing the type and grade of plywood helps you prepare for the cutting process and choose the right blade and cutting technique when using a circular saw to cut plywood.

Safety Precautions Before Cutting

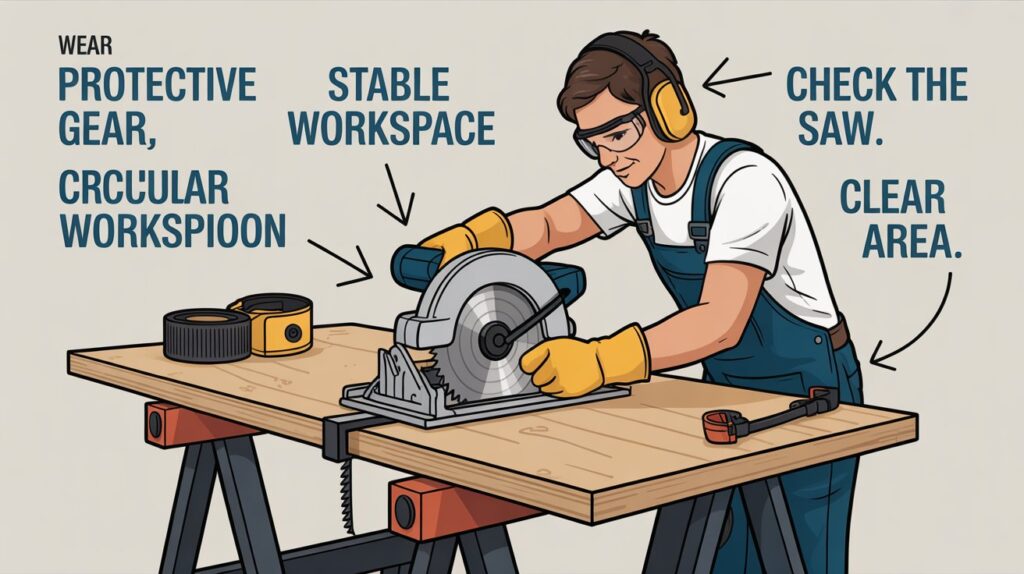

Using a circular saw to cut plywood can be quick and efficient, but it also comes with safety risks. Taking proper precautions ensures that your work is safe and your cuts are accurate.

- Wear protective gear: Always wear safety goggles to protect your eyes from sawdust and flying wood particles. Gloves can protect your hands, and hearing protection is recommended for prolonged use.

- Stable workspace: Ensure your plywood is supported on a flat surface or sawhorses. Unstable surfaces can cause the saw to slip and result in uneven cuts or accidents.

- Check the saw: Inspect your circular saw before use. Make sure the blade is sharp, properly installed, and free of damage. Also, check that the power cord or battery is in good condition.

- Clear the area: Remove any obstacles or debris from your cutting area. Keep children and pets away to prevent distractions or accidents.

By following these safety measures, you can confidently achieve precise results while using a circular saw to cut plywood.

Measuring and Marking Plywood

Accurate measurements and markings are essential when using a circular saw to cut plywood. Mistakes at this stage can lead to uneven cuts and wasted material.

- Measure twice: Use a tape measure to determine the exact dimensions you need. Double-check measurements to avoid errors.

- Mark clearly: Draw cut lines with a pencil or chalk. A straightedge or ruler ensures your lines are straight and precise.

- Consider the blade width: When marking, remember the saw blade has thickness. Position your line so the cut will be on the correct side.

- Use guides if needed: For long cuts, a straight edge or guide clamp can help the circular saw move smoothly and prevent deviations.

Proper measuring and marking make using a circular saw to cut plywood easier and result in clean, accurate edges.

Setting Up the Circular Saw

Proper setup is important when using a circular saw to cut plywood. Correct adjustments ensure smooth, precise cuts and reduce the risk of mistakes or accidents.

- Adjust the blade depth: Set the blade so it extends about 1/8 to 1/4 inch below the plywood. A blade that is too deep can cause splintering and is less safe.

- Check the bevel angle: For angled cuts, adjust the bevel to the desired degree. For standard straight cuts, keep the blade at 0 degrees.

- Secure the saw: Make sure the shoe of the saw rests flat on the plywood before starting. This prevents the saw from tilting or binding.

- Test the saw: Turn it on briefly above the cut line to ensure it is running smoothly. This step helps avoid surprises while cutting.

Following these setup steps makes using a circular saw to cut plywood more accurate and safer.

Cutting Techniques

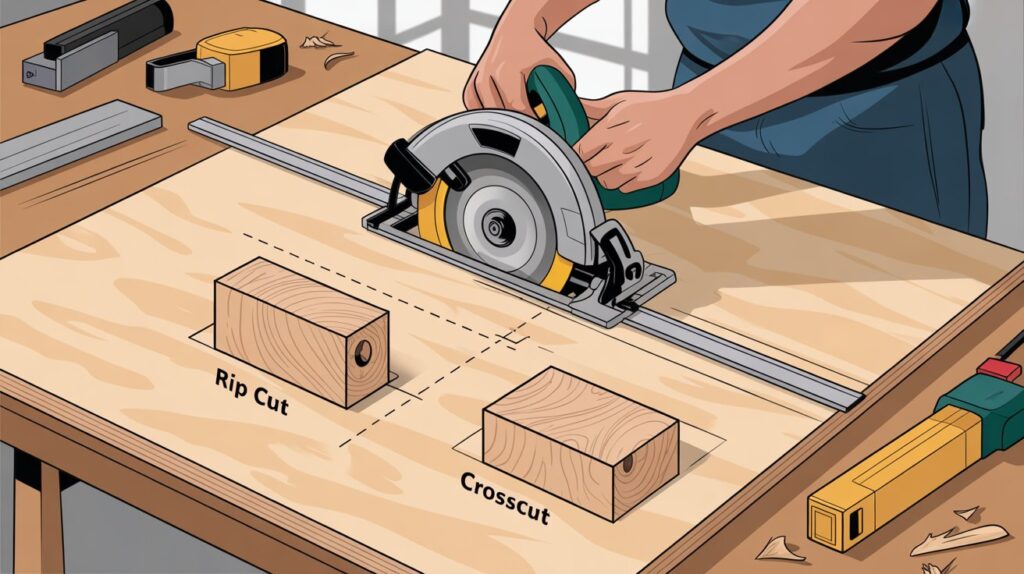

Using the right cutting techniques is essential when using a circular saw to cut plywood. Proper technique ensures straight, clean cuts and reduces splintering.

- Straight cuts: Keep the saw steady and follow the marked line carefully. Use both hands to control the saw and move it slowly along the guide or straightedge.

- Rip cuts vs. crosscuts: Rip cuts go along the grain of the plywood, while crosscuts go across the grain. Use a slower speed on crosscuts to prevent chipping.

- Control speed and pressure: Let the saw do the work. Apply gentle, consistent pressure and avoid forcing the blade through the plywood too quickly.

- Use guides for long cuts: For longer cuts, clamp a straightedge to the plywood. This helps keep the saw on track and improves accuracy.

By mastering these cutting techniques, using a circular saw to cut plywood becomes easier, safer, and produces professional-looking results.

Preventing Splintering

Splintering is a common issue when using a circular saw to cut plywood. Taking a few simple steps can help achieve smooth edges.

- Use painter’s tape: Apply tape along the cut line. This supports the wood fibers and reduces splintering.

- Score the cut line: Lightly score the line with a utility knife before cutting. This creates a clean edge for the saw to follow.

- Choose the right blade: Fine-toothed blades designed for plywood reduce tear-out and splintering.

- Cut face down or up depending on saw type: For circular saws, the splintering usually occurs on the side where the blade exits the wood. Position the plywood so the finished side faces the proper direction.

Following these steps makes using a circular saw to cut plywood cleaner and results in smoother edges.

Handling Large Sheets

Working with large plywood sheets requires care when using a circular saw to cut plywood. Proper handling ensures safety and accuracy.

- Support the plywood: Use sawhorses or a stable workbench to prevent bending or sagging. Unsupported sheets can cause uneven cuts.

- Work with a partner: For very large sheets, having someone help hold and guide the plywood makes cutting easier and safer.

- Move slowly: Large sheets are harder to control. Take your time and ensure the saw follows the marked line accurately.

- Clear space: Make sure there is enough room around you to maneuver the sheet without hitting obstacles.

Following these tips ensures that using a circular saw to cut plywood is safe and produces straight, precise cuts even with large sheets.

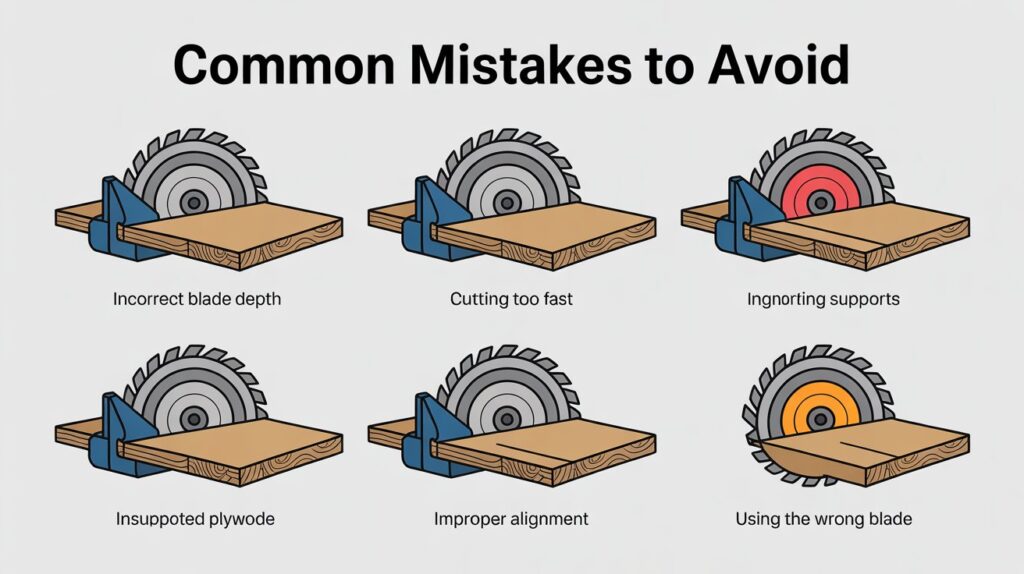

Common Mistakes to Avoid

Avoiding mistakes is key when using a circular saw to cut plywood. Being aware of common errors can save time, material, and prevent accidents.

- Incorrect blade depth: Setting the blade too deep can cause splintering and make the saw harder to control. Too shallow may not cut through the plywood completely.

- Cutting too fast: Rushing through a cut can lead to rough edges and uneven lines. Move the saw steadily and let the blade do the work.

- Ignoring supports: Cutting plywood without proper support can cause bending or pinching, resulting in inaccurate cuts.

- Improper alignment: Not following the marked line carefully can ruin the cut. Always check alignment before starting.

- Using the wrong blade: Blades with too few teeth or damaged blades can cause tear-out and poor quality cuts.

Being mindful of these mistakes makes using a circular saw to cut plywood easier, safer, and produces professional results.

Finishing the Cut

After using a circular saw to cut plywood, finishing the cut properly ensures smooth edges and a professional result.

- Check the edges: Inspect the cut for any splintering or unevenness. Minor rough spots can be fixed with sanding.

- Sand the edges: Use fine-grit sandpaper to smooth the edges. This prevents splinters and improves the appearance of the plywood.

- Clean the surface: Remove sawdust and debris from the cut area. A clean surface makes assembly or further work easier.

- Verify dimensions: Measure the piece after cutting to confirm it matches your intended size before proceeding with the project.

Finishing the cut carefully makes using a circular saw to cut plywood more precise and prepares the material for the next step in your project.

Maintaining Your Circular Saw

Proper maintenance of your tool is important when using a circular saw to cut plywood. A well-maintained saw works efficiently and lasts longer.

- Clean the saw regularly: Remove sawdust and debris from the blade, motor, and vents. This prevents overheating and ensures smooth operation.

- Check the blade: Inspect for dullness or damage. A sharp blade makes cleaner cuts and reduces the risk of splintering. Replace the blade when needed.

- Lubricate moving parts: Apply light oil to the moving parts of the saw to keep it running smoothly.

- Store safely: Keep the saw in a dry place, away from moisture and dust, and unplug or remove the battery when not in use.

By maintaining your tool, using a circular saw to cut plywood becomes safer, easier, and produces better results.

Conclusion

Using a circular saw to cut plywood can be simple and efficient when you follow the right steps. From choosing the correct saw and plywood to measuring accurately, setting up properly, and using the right cutting techniques, every step affects the quality of your cut. Paying attention to safety, preventing splintering, and maintaining your saw ensures smooth, precise, and professional results.

With careful preparation and practice, even beginners can achieve clean cuts and handle large sheets of plywood confidently. Following these tips will make your projects faster, safer, and more successful.

FAQs

1. What type of blade is best for cutting plywood with a circular saw?

A fine-toothed plywood blade is best. It reduces splintering and creates smoother edges compared to standard blades.

2. Should I cut plywood face up or face down?

For most circular saws, the finished side of the plywood should face down. This minimizes splintering on the visible side of the sheet.

3. How can I prevent plywood from splintering when cutting?

Use painter’s tape along the cut line, score the line lightly with a utility knife, and use a fine-toothed blade. Cutting slowly and steadily also helps.

4. Is it safer to use a corded or cordless circular saw for plywood?

Both can be safe if used correctly. Corded saws provide consistent power for long cuts, while cordless saws offer more mobility. Choose based on your workspace and project size.

5. How do I handle large plywood sheets when cutting?

Support the sheet on sawhorses or a stable surface, work with a partner if needed, and ensure there is enough space to maneuver the sheet safely.