Introduction

Table saw blades are the heart of every woodworking project, directly impacting cut quality, precision, and safety. Selecting the right blade can make the difference between rough, uneven cuts and smooth, professional results. In this guide, we explore everything you need to know about table saw blades, including types, sizes, tooth count, materials, maintenance, and safety tips, to help you choose the best blade for your projects.

Table of Contents

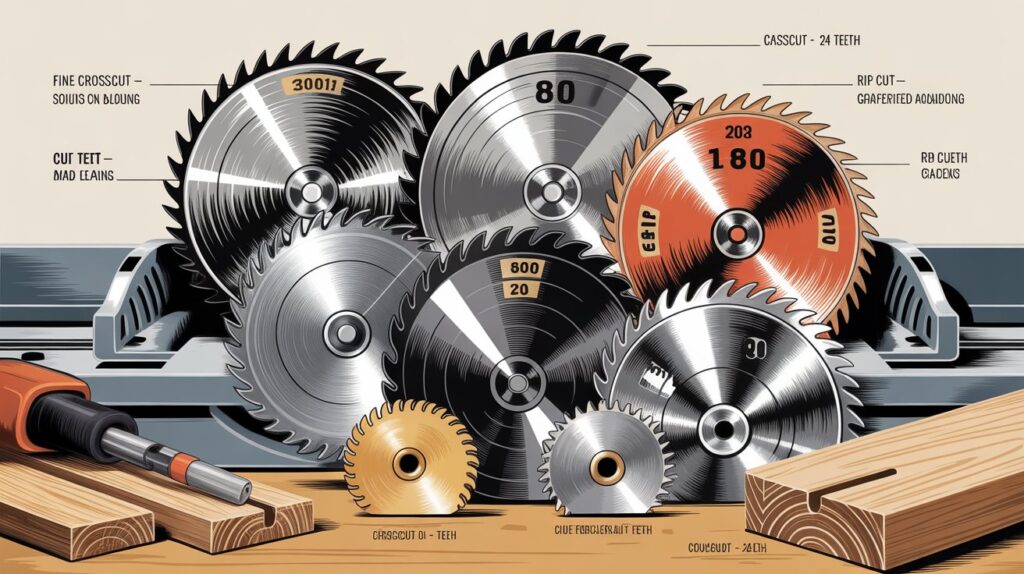

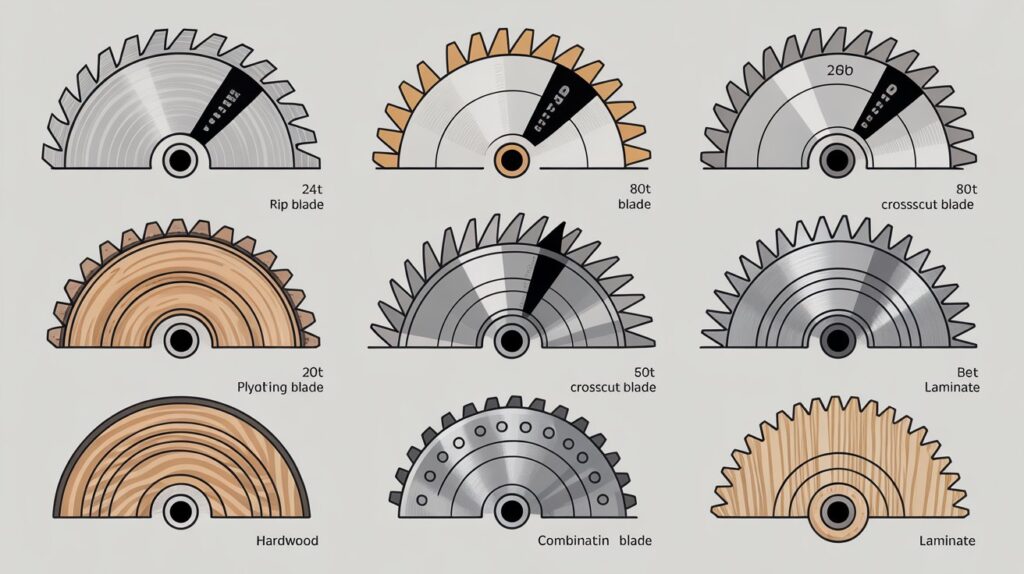

Types of Table Saw Blades and Their Uses

Choosing the correct type of table saw blades is essential for achieving clean, accurate, and efficient cuts. Each blade type is designed for a specific purpose, and using the right one improves performance, safety, and overall results. Below is a detailed breakdown of the most common table saw blade types and how they are used in woodworking.

Rip Cut Table Saw Blades

Rip cut table saw blade options are designed specifically for cutting wood along the grain. These blades usually have a low tooth count, typically between 24 and 30 teeth. Fewer teeth allow faster material removal and reduce strain on the saw motor.

This type of table saw blade for wood is ideal for cutting thick hardwoods and softwoods efficiently. While rip blades cut quickly, the finish may be rougher compared to blades with a higher tooth count, making them better suited for structural cuts rather than fine finishing.

Crosscut Table Saw Blades

A crosscut table saw blade is designed to cut across the grain of the wood. These blades usually feature 60 to 80 teeth, which helps create smoother and cleaner edges. The higher tooth count reduces tear-out and splintering, especially on hardwoods and plywood.

Crosscut blades are commonly used in furniture making, cabinetry, and trim work where precision and surface quality matter. They are an important category of professional table saw blades for detail-oriented projects.

Combination Table Saw Blades

A combination table saw blade is a versatile option that can handle both rip cuts and crosscuts. These blades typically have 40 to 50 teeth arranged in a mixed pattern to balance speed and smoothness.

Combination blades are popular among DIY users and professionals who want one reliable table saw cutting blade for general woodworking tasks. They are often considered the best starting point in any table saw blade guide.

Dado Table Saw Blades

Dado blades are specialized table saw blades used for cutting grooves, dados, and rabbets. They are commonly sold as stacked sets that allow users to adjust the width of the cut.

These blades are essential for joinery work, shelving, and cabinet construction. Because of their specialized design, dado blades require compatible table saws and proper setup to ensure safe operation and accurate cuts.

Thin Kerf Table Saw Blades

A thin kerf table saw blade removes less material during cutting, making it easier on saw motors with lower horsepower. These blades are ideal for portable or compact table saws.

Thin kerf blades improve cutting efficiency and reduce waste, but they require proper alignment to prevent blade deflection. They are often chosen for precise woodworking where material conservation is important.

Carbide Tipped Table Saw Blades

A carbide tipped table saw blade features teeth reinforced with carbide, a material known for its durability and heat resistance. These blades stay sharp longer than standard steel blades and offer consistent performance over time.

Carbide-tipped blades are widely used in high quality table saw blades because they provide excellent cutting results and longer lifespan, making them a cost-effective choice for frequent use.

Plywood and Laminate Table Saw Blades

These table saw blade types are designed specifically to cut plywood, veneers, and laminated materials. They often feature a high tooth count and specialized tooth geometry to minimize chipping.

They are commonly used in cabinetry and interior finishing projects where surface appearance is critical. These blades support smooth cutting and clean wood cuts on delicate materials.

Specialty Table Saw Blades

Specialty blades include options designed for non-ferrous metals, plastics, and composite materials. These woodworking saw blades are engineered with unique tooth configurations to handle harder or more brittle materials safely.

They are used in advanced woodworking and construction applications where standard blades may not perform effectively.

Choosing the Right Blade Type

Selecting the correct blade depends on the material, cut direction, and desired finish. Understanding table saw blade features, such as tooth count, blade material, and kerf width, helps improve overall table saw blade performance.

Using the right blade type not only enhances cutting accuracy but also extends blade life and improves workshop safety.

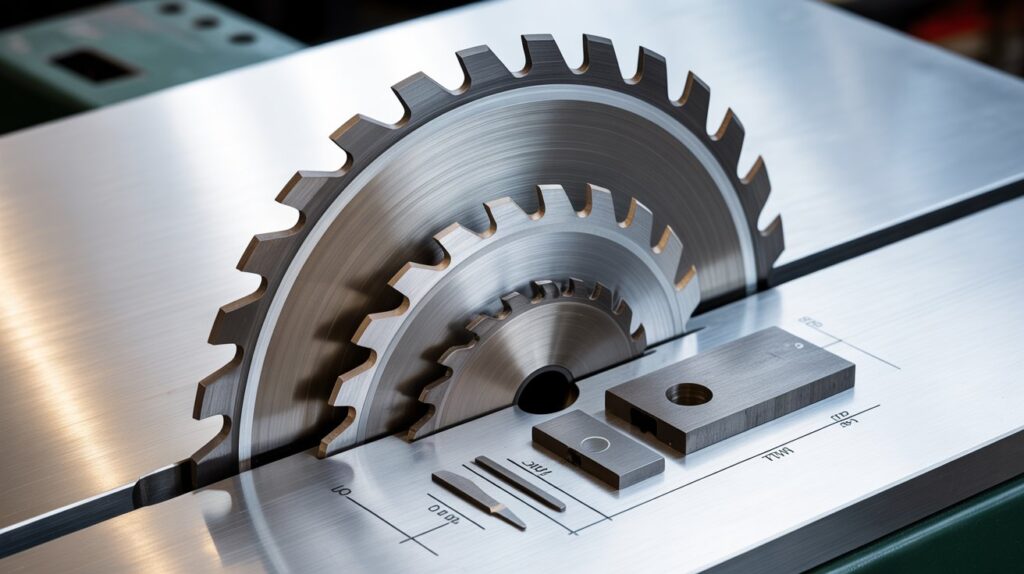

Blade Size and Table Saw Compatibility

Selecting the correct blade size is a critical factor in achieving safe and accurate cuts. Table saw blades must match your saw’s specifications to deliver optimal performance and prevent mechanical issues. Understanding blade size and compatibility helps improve cutting accuracy, efficiency, and overall table saw blade performance.

Common Table Saw Blade Sizes

The most widely used table saw blade size is the 10-inch blade, which is standard for most contractor and cabinet table saws. Portable and compact saws often use 8-1/4-inch blades, while heavy-duty industrial saws may support 12-inch blades.

Choosing the correct size ensures proper cutting depth and smooth operation. Using an incorrect blade size can limit cutting capacity and affect the quality of cutting wood with table saw equipment.

Arbor Size and Blade Fit

Arbor size refers to the diameter of the hole at the center of the blade. Most table saw blades are designed with a 5/8-inch arbor, which fits standard table saws. Some older or specialized models may require different arbor sizes.

Proper arbor fit is essential for stability. A poorly fitted blade can wobble during operation, reducing accuracy and creating safety risks. Always confirm arbor compatibility before installing any table saw cutting blades.

Blade Thickness and Kerf Considerations

Blade thickness, also known as kerf width, affects both compatibility and performance. Full-kerf blades typically measure about 1/8 inch and are ideal for powerful saws. Thin-kerf blades remove less material and are better suited for saws with lower horsepower.

Choosing the correct kerf improves cutting efficiency and reduces strain on the motor. This factor plays an important role in table saw blade selection, especially for smaller saws.

Maximum RPM Ratings

Every table saw blade includes a maximum RPM rating that must exceed the operating speed of your saw. Exceeding this rating can cause blade failure and serious safety hazards.

Always check manufacturer guidelines to ensure compatibility. Matching RPM ratings ensures smooth cutting and long-term durability of high quality table saw blades.

Compatibility with Different Table Saw Types

Different table saw types require specific blade considerations. Contractor saws commonly use standard-size blades, while portable saws benefit from lightweight and thin-kerf options. Cabinet saws can support heavier professional table saw blades designed for continuous use.

Understanding your saw type helps in selecting woodworking saw blades that deliver clean wood cuts and reliable performance.

Safety and Performance Impact

Using compatible blade sizes improves stability and reduces vibration. Properly matched table saw blades enhance accuracy and minimize wear on both the blade and the saw.

Correct compatibility also supports safe operation, making it easier to maintain control during cuts and achieve consistent results.

Tooth Count and Its Impact on Cutting Quality

The number of teeth on table saw blades has a direct effect on cutting speed, surface finish, and overall accuracy. Understanding how tooth count influences performance helps in making the right table saw blade selection for different woodworking tasks.

How Tooth Count Affects Cutting Performance

Tooth count determines how aggressively a blade cuts through material. Table saw cutting blades with fewer teeth remove material quickly, while blades with more teeth produce smoother finishes. Selecting the correct tooth count improves table saw blade performance and ensures consistent results.

A balanced tooth count also reduces strain on the saw motor and supports clean wood cuts.

Low Tooth Count Blades for Fast Cutting

Blades with 24 to 30 teeth are ideal for fast, rough cuts, especially when cutting along the grain. These blades are commonly used as a rip cut table saw blade and are effective for processing thick lumber.

Low tooth count table saw blades are best suited for structural work where speed is more important than surface smoothness.

High Tooth Count Blades for Smooth Finishes

Blades with 60 to 80 teeth are designed for fine cutting and clean edges. A crosscut table saw blade with a high tooth count reduces tear-out and delivers superior surface quality.

These professional table saw blades are preferred for furniture making, cabinetry, and trim work where precision is essential.

Medium Tooth Count for Versatility

Blades with 40 to 50 teeth are often classified as combination table saw blade options. They offer a balance between cutting speed and finish quality, making them suitable for general woodworking tasks.

This tooth count is commonly recommended in any table saw blade guide for users who want a single blade for multiple applications.

Tooth Count and Material Type

Different materials require different tooth counts. Hardwoods, plywood, and laminates benefit from higher tooth counts, while softwoods and thick boards cut more efficiently with fewer teeth.

Choosing the correct tooth count for your table saw blade for wood helps prevent burning, splintering, and uneven cuts.

Impact on Safety and Blade Life

Proper tooth count selection improves control and reduces kickback risks. Using the right high quality table saw blades also minimizes wear, helping the blade stay sharp longer.

Correct tooth configuration contributes to safer operation and better long-term performance of woodworking saw blades.

Choosing the Right Tooth Count

Understanding tooth count allows for smarter blade choices based on project requirements. Matching tooth count to cutting needs ensures smooth operation, clean wood cuts, and reliable results.

Selecting the right tooth count is a key factor in achieving consistent quality with table saw blades.

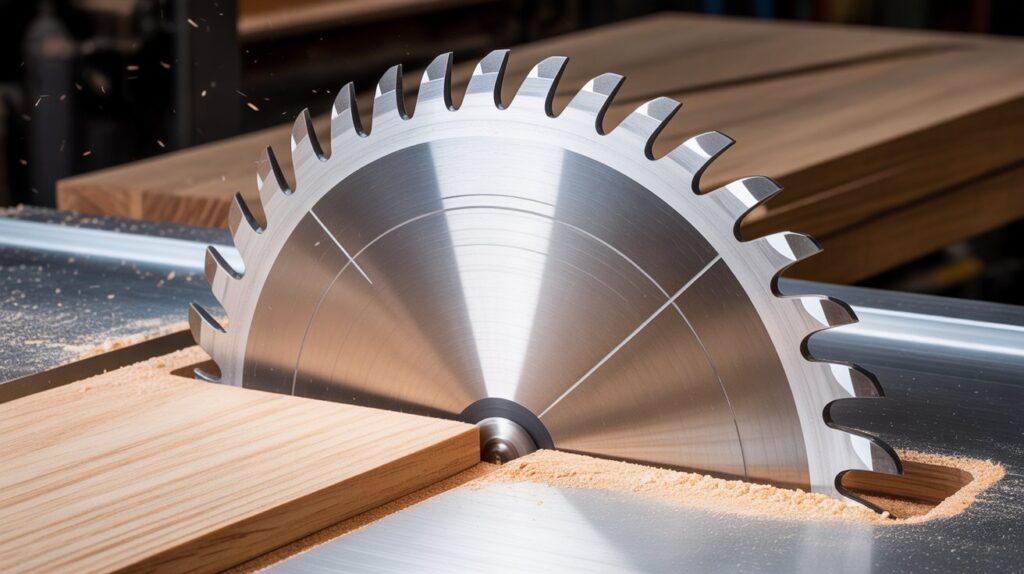

Tooth Geometry and Blade Design

The design of table saw blades and the geometry of their teeth play a critical role in cutting efficiency, precision, and finish quality. Understanding tooth geometry and blade design is essential for selecting the right table saw blade for wood and achieving professional results.

Understanding Tooth Geometry

Tooth geometry refers to the shape, angle, and spacing of the teeth on a table saw blade. These factors determine how the blade interacts with the material, affecting speed, smoothness, and durability.

Proper tooth geometry ensures clean cuts, reduces tear-out, and improves overall table saw blade performance. Different woodworking applications require different tooth designs for optimal results.

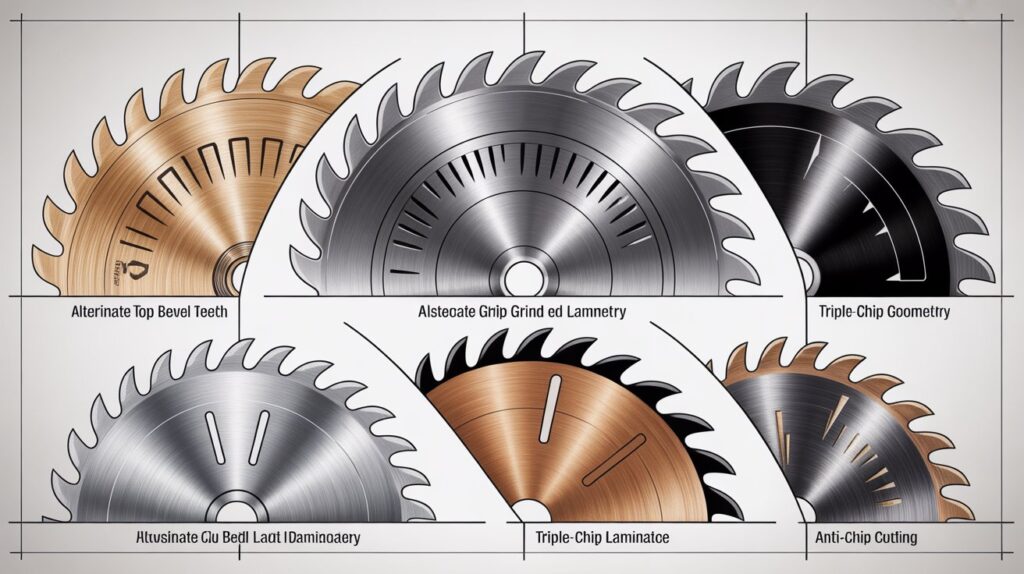

Common Tooth Geometries

- Flat Top Grind (FTG)

- Teeth have a flat top surface.

- Best suited for ripping along the grain of wood.

- Common in rip cut table saw blades due to aggressive material removal.

- Alternate Top Bevel (ATB)

- Teeth alternate between left and right bevels.

- Ideal for clean crosscuts and fine finishing.

- Reduces splintering on plywood and laminates.

- Combination Tooth (ATB + Raker)

- A mix of ATB and flat teeth.

- Found in combination table saw blades.

- Balances cutting speed and smoothness for general woodworking.

- Triple Chip Grind (TCG)

- Alternates a flat-top tooth with two trapezoidal teeth.

- Designed for cutting hard materials, laminates, and non-ferrous metals.

- Provides long-lasting performance with minimal chipping.

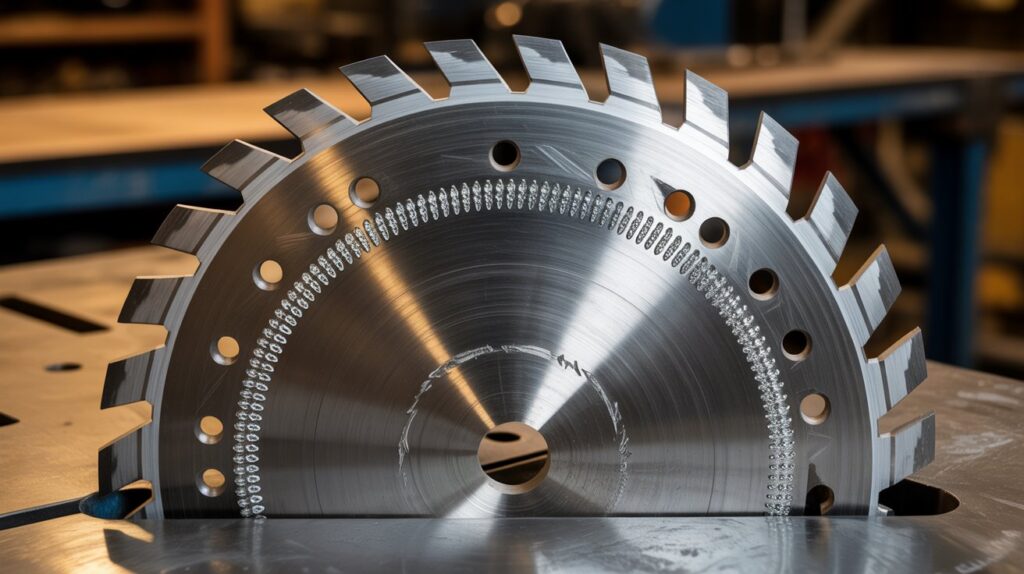

Blade Design Considerations

Blade design extends beyond tooth geometry. Factors such as body thickness, gullets, coating, and heat resistance influence the performance of table saw cutting blades.

- Body thickness: Full-kerf blades provide stability; thin-kerf blades reduce material waste and saw motor load.

- Gullets: Spaces between teeth allow debris removal, essential for faster cuts and cooler operation.

- Coatings: Anti-friction coatings prevent resin build-up and improve durability.

Choosing the right combination of tooth geometry and blade design ensures smooth wood cuts, higher efficiency, and longer blade life.

Impact on Cutting Quality

Correct tooth geometry and blade design directly influence the quality of cuts. A blade with inappropriate tooth design may burn wood, cause tear-out, or wear quickly.

Selecting the proper blade improves safety, precision, and finish quality. High-quality professional table saw blades are engineered to match specific cutting tasks and materials.

Selecting the Right Tooth Geometry

When choosing table saw blades, consider:

- The type of cut (rip, crosscut, combination)

- Material hardness (softwood, hardwood, plywood)

- Finish quality required

- Matching tooth geometry and blade design to your woodworking project ensures clean, precise, and efficient results with minimal effort.

Blade Materials and Carbide Tipping

The material and construction of table saw blades are key factors that determine cutting performance, durability, and precision. Understanding blade materials and carbide tipping is essential for selecting the right table saw blade for wood and maximizing efficiency in woodworking projects.

Common Blade Materials

Table saw blades are typically made from one of the following materials:

- High-Speed Steel (HSS)

- Durable and capable of cutting soft and hardwoods.

- Less expensive but dulls faster than carbide-tipped blades.

- Suitable for light-duty and occasional use.

- Carbide-Tipped Steel

- Teeth are coated with carbide for increased hardness.

- Maintains sharpness longer than HSS blades.

- Ideal for frequent use and cutting hardwoods, plywood, and laminates.

- Solid Carbide

- Entire blade is made of carbide.

- Extremely durable and resistant to heat and wear.

- Mostly used in professional and industrial professional table saw blades.

Advantages of Carbide Tipping

Carbide tipped table saw blades are widely preferred for their enhanced performance:

- Longer Lifespan: Carbide teeth retain sharpness longer, reducing the frequency of sharpening.

- Consistent Cutting Quality: Maintains smooth and precise cuts throughout its lifespan.

- Heat Resistance: Carbide tips resist heat buildup, which minimizes burning and warping of wood.

- Versatility: Suitable for hardwood, softwood, plywood, laminates, and composite materials.

These features make carbide-tipped blades a popular choice in any table saw blade guide and a key factor in table saw blade selection.

Impact on Cutting Performance

The material of a table saw blade affects speed, finish, and efficiency. Carbide-tipped blades allow for faster cuts without sacrificing quality, while HSS or steel blades may require slower feed rates to avoid dulling.

High-quality table saw cutting blades with carbide tips reduce tear-out and produce cleaner edges, especially on delicate materials like veneers and laminates. Proper material selection ensures consistent table saw blade performance and safer operation.

Maintenance Considerations

While carbide tipped table saw blades are durable, proper maintenance is still necessary:

- Clean resin and pitch buildup regularly to maintain cutting efficiency.

- Avoid cutting materials that exceed the blade’s specifications to prevent damage.

- Store blades in a dry, safe location to avoid corrosion and chipping.

Following these practices extends the lifespan of high-quality woodworking saw blades.

Choosing the Right Blade Material

When selecting table saw blades, consider:

- Frequency of use

- Types of materials being cut

- Desired cutting precision and finish

For most woodworking projects, carbide tipped table saw blades offer the best balance of durability, performance, and reliability. Investing in high-quality materials ensures consistent results and long-term savings.

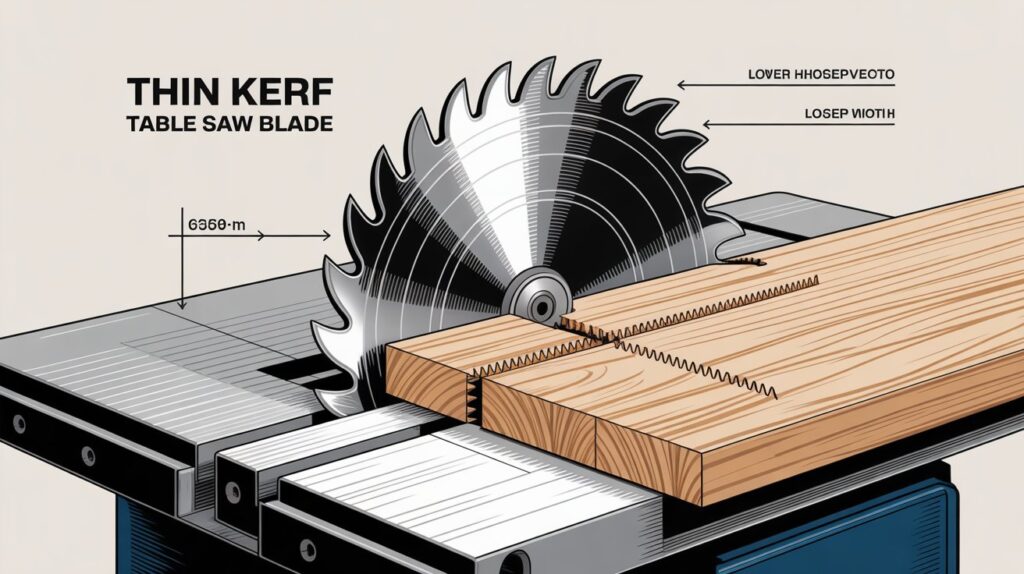

Kerf Width and Cutting Performance

The kerf width of table saw blades is a key factor that affects cutting efficiency, precision, and material waste. Understanding the relationship between kerf width and cutting performance helps woodworkers select the best table saw blade for wood for any project.

What is Kerf Width?

Kerf width refers to the thickness of the cut made by a table saw blade. It is determined by the width of the blade teeth and the amount of material removed during cutting. The kerf impacts the load on the saw motor, cut smoothness, and material consumption.

Choosing the appropriate kerf is crucial for achieving accurate, clean cuts and maintaining table saw blade performance.

Full-Kerf Blades

Full-kerf table saw blades typically have a kerf width of around 1/8 inch (3.2 mm). These blades are thicker and provide:

- Enhanced stability during cutting

- Reduced vibration

- Better performance on heavy-duty saws

Full-kerf blades are ideal for high-power table saws and professional woodworking where precision and control are essential. They are commonly used as professional table saw blades in workshops and production environments.

Thin-Kerf Blades

Thin-kerf table saw blades remove less material, usually around 3.0 mm or less. They offer several advantages:

- Require less motor power, making them suitable for portable or low-horsepower saws

- Reduce material waste

- Allow faster feed rates on softwoods and thinner stock

Thin-kerf blades are popular for DIY woodworking and projects where efficiency and resource conservation are important. They are also effective in producing smooth wood cuts without overloading the saw.

Impact on Cutting Performance

The kerf width directly influences cutting speed, finish, and saw efficiency:

- Wider kerf blades provide more stability and cleaner cuts on hardwoods but require more power.

- Narrow kerf blades allow faster cuts and reduce stress on the saw motor but may be less stable on thick stock.

Choosing the right kerf ensures optimal table saw blade performance for your specific application.

Choosing the Right Kerf Width

When selecting a table saw blade, consider:

- Saw horsepower and type

- Material thickness and hardness

- Desired cutting speed and finish quality

Using the correct kerf width enhances cutting efficiency, minimizes material waste, and improves overall safety when using table saw cutting blades.

Maintenance Considerations

Both full-kerf and thin-kerf blades benefit from proper maintenance:

- Clean resin and pitch buildup to maintain cutting efficiency

- Inspect teeth regularly for wear and damage

- Store blades in a dry, safe location to prevent warping or corrosion

Proper care ensures long-term performance and consistent high quality table saw blades results.

Choosing the Right Table Saw Blade for Your Project

Selecting the correct table saw blade is essential for achieving clean, precise, and efficient cuts. The right blade improves table saw blade performance, ensures safety, and extends the lifespan of both the blade and the saw. This guide will help you make informed decisions when choosing a table saw blade for wood.

Consider the Type of Cut

The first factor in table saw blade selection is the type of cut required:

- Rip Cuts: Use a rip cut table saw blade with fewer teeth for fast material removal along the grain.

- Crosscuts: A crosscut table saw blade with more teeth ensures smooth, clean edges when cutting across the grain.

- Combination Cuts: For projects requiring both rip and crosscuts, a combination table saw blade provides balanced performance.

Matching the blade type to your project ensures accuracy and reduces the risk of tear-out.

Material of the Workpiece

Different materials require specific table saw cutting blades:

- Softwoods: Low tooth count blades cut efficiently.

- Hardwoods: Carbide-tipped blades with higher tooth count maintain precision.

- Plywood and Laminates: High tooth count and specialized tooth geometry prevent splintering.

- Non-Ferrous Metals and Plastics: Specialty woodworking saw blades are designed for clean, safe cuts.

Selecting the right material-specific blade improves finish quality and protects the blade from premature wear.

Blade Size and Kerf Width

Ensure the table saw blade size is compatible with your saw and suitable for the project. Blade diameter affects cutting depth, while kerf width influences stability and motor load:

- Full-kerf blades offer stability for thick stock.

- Thin-kerf blades are ideal for portable saws and thin material.

Proper sizing ensures efficient, safe, and precise cuts.

Tooth Count and Geometry

The tooth count and tooth geometry directly affect cut quality:

- Fewer teeth for fast, rough cuts.

- More teeth for smooth, fine finishes.

- Specific tooth geometries, such as ATB or TCG, improve cutting efficiency for certain materials.

Understanding these features ensures the blade matches the project requirements.

Blade Material and Durability

High-quality table saw blades with carbide tipping or solid carbide teeth provide longer lifespan and better performance. For frequent or professional use, investing in durable blades ensures consistent results and reduces maintenance.

Maintenance and Safety Considerations

Maintaining your blade is crucial for performance:

- Clean resin and pitch buildup regularly.

- Inspect teeth for damage before use.

- Ensure proper arbor fit and blade alignment.

Following these practices enhances table saw blade performance and ensures safe operation.

Making the Right Choice

When choosing a table saw blade for your project, consider:

- Cut type (rip, crosscut, combination)

- Material being cut

- Saw type and horsepower

- Desired finish quality

- Blade durability and maintenance

Selecting the correct blade ensures efficiency, safety, and high-quality results in every woodworking project.

Maintenance, Cleaning, and Blade Lifespan

Proper care and maintenance of table saw blades are essential for ensuring consistent cutting performance, extending blade life, and maintaining safety. Understanding how to clean, inspect, and store your blades will maximize the efficiency of your table saw blade for wood.

Importance of Maintenance

Regular maintenance improves table saw blade performance by keeping teeth sharp, preventing resin buildup, and avoiding damage. Well-maintained blades produce smoother cuts, reduce tear-out, and place less strain on the saw motor. Neglecting maintenance can result in dull cuts, uneven edges, and decreased blade lifespan.

Cleaning Your Table Saw Blades

Table saw cutting blades accumulate resin, pitch, and dust over time, which affects cutting efficiency. To clean your blades:

- Remove the blade from the saw following safety guidelines.

- Scrub gently with a soft brush to remove buildup from teeth and gullets.

- Dry thoroughly to prevent corrosion before reinstallation.

Regular cleaning ensures optimal performance and helps maintain high quality table saw blades for longer periods.

Sharpening and Tooth Care

Maintaining sharp teeth is critical for consistent results:

- Carbide-tipped table saw blades can be professionally sharpened when dull.

- Avoid cutting materials that exceed the blade’s design to prevent premature wear.

- Inspect teeth for chips or damage regularly to ensure safe operation.

Proper sharpening and inspection maintain the precision of your table saw cutting blades and enhance the quality of your cuts.

Proper Storage

Correct storage prevents warping, corrosion, and accidental damage:

- Store blades in a dry, cool environment.

- Use blade guards or cases to protect teeth.

- Keep blades organized to prevent contact with other tools or blades.

Safe storage extends the lifespan of professional table saw blades and keeps them ready for immediate use.

Blade Lifespan Considerations

The lifespan of table saw blades depends on:

- Frequency of use

- Material being cut

- Blade material and tooth design

- Maintenance and cleaning routines

High-quality carbide tipped table saw blades can last for years with proper care, while cheaper steel blades may require more frequent replacement. Choosing durable blades and maintaining them properly ensures long-term efficiency and consistent results.

Safety Tips During Maintenance

Always follow safety protocols when maintaining table saw blades:

- Disconnect the saw from power before removing the blade.

- Wear gloves to protect hands from sharp teeth.

- Handle blades carefully to avoid damage or injury.

Safe maintenance practices protect both the operator and the blade, ensuring reliable table saw blade performance

Safety Tips When Using Table Saw Blades

Using table saw blades safely is essential for preventing accidents and achieving precise, professional results. Understanding proper safety techniques protects both the operator and the table saw blade for wood, ensuring consistent table saw blade performance over time.

Always Use Personal Protective Equipment

Before operating any table saw, wear the appropriate safety gear:

- Wear safety glasses or a face shield to guard your eyes from flying debris.

- Hearing protection to reduce noise exposure

- Gloves when handling blades, but not while operating the saw

Personal protective equipment is critical when using table saw cutting blades to prevent injuries during woodworking.

Proper Blade Installation

Correct installation of table saw blades ensures stability and accuracy:

- Disconnect the saw from power before changing blades

- Ensure the blade arbor matches the table saw blade size

- Tighten the arbor nut securely to prevent wobbling

Proper installation improves high quality table saw blades performance and reduces risks during operation.

Use Blade Guards and Safety Accessories

Always utilize blade guards, riving knives, and anti-kickback devices:

- Blade guards cover exposed teeth to prevent contact

- Riving knives reduce the risk of kickback

- Push sticks or push blocks help maintain a safe distance from the blade

These accessories are essential for safe handling of professional table saw blades during cuts.

Correct Cutting Techniques

Following proper cutting techniques improves safety and cutting quality:

- Feed material at a steady pace without forcing it

- Keep hands away from the cutting path

- Support long or wide boards to prevent binding

Safe cutting techniques optimize table saw blade performance and minimize material waste.

Maintenance and Inspection for Safety

Regular inspection of table saw blades prevents accidents and ensures efficient operation:

- Check for chipped or damaged teeth

- Clean resin and pitch buildup regularly

- Verify that blades are sharp and aligned

Maintaining table saw cutting blades reduces the likelihood of kickback and improves cutting accuracy.

Avoid Common Mistakes

Common mistakes that compromise safety include:

- Using the wrong blade type for the material

- Cutting without guards or push sticks

- Forcing material through the blade

Avoiding these errors ensures safe use of table saw blades and consistent woodworking saw blades performance.

Emergency Preparedness

Be prepared for emergencies by:

- Knowing the location of the power switch

- Keeping a first-aid kit nearby

- Understanding how to stop the saw quickly

Emergency preparedness complements all other safety measures when working with table saw blades.

Conclusion

Choosing the right table saw blades is essential for achieving clean, precise, and efficient cuts in any woodworking project. From understanding blade types, sizes, tooth count, and tooth geometry to selecting the appropriate material and maintaining the blade properly, every factor affects table saw blade performance. By investing in high-quality blades, following proper maintenance routines, and using safe cutting techniques, you can enhance accuracy, extend blade lifespan, and ensure professional results in all your woodworking tasks.

FAQs

Q.1 What is the importance of tooth count on table saw blades?

Tooth count affects cutting speed and finish quality. Fewer teeth are ideal for rip cuts, while more teeth provide smoother crosscuts.

Q.2 What materials are table saw blades made from?

Table saw blades are commonly made from high-speed steel, carbide-tipped steel, or solid carbide, each offering different durability and cutting performance.

Q.3 How can I maintain and extend the lifespan of table saw blades?

Regular cleaning, proper sharpening, correct storage, and avoiding cutting materials beyond the blade’s specifications help maintain performance and longevity.

Q. 4 What size blade do most table saws take?

Most table saws use a 10-inch blade, which offers the right balance of cutting depth, accuracy, and versatility for general woodworking tasks.

Q. 5 What is a 40-tooth saw blade used for?

A 40-tooth saw blade is commonly used as a combination blade, suitable for both rip cuts and crosscuts, providing a good balance between cutting speed and smooth finish.