Introduction

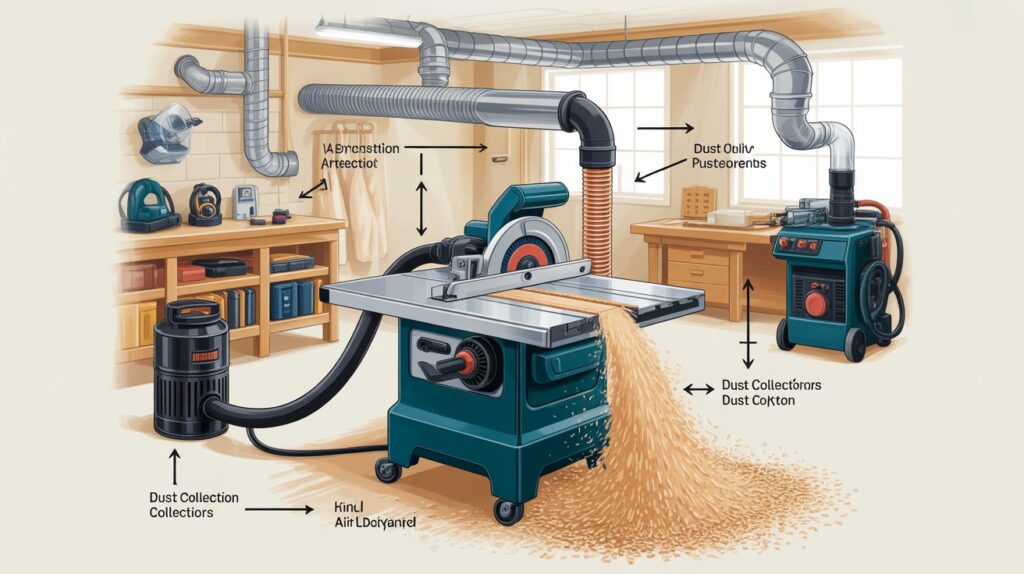

Tablesaw dust collection is a critical part of any woodworking setup, yet many users overlook it. Every cut produces fine dust and chips that can affect your health, reduce cutting accuracy, and create a messy workspace. In this guide, we will explore practical methods, systems, and accessories that improve dust control, helping you maintain a cleaner, safer, and more efficient workshop.

Table of Contents

Why Dust Control Is Essential for a Table Saw

Dust collection for table saw and User Health

Wood dust released during cutting is not just messy; it can be harmful when inhaled regularly. Fine particles stay suspended in the air and may enter the lungs, causing respiratory irritation over time. Proper managing dust from table saw reduces airborne particles and creates a safer environment for long working sessions.

Cabinet Table Saw Dust Collection and Machine Performance

Dust buildup inside the saw cabinet can interfere with internal components, restrict airflow, and lead to overheating. An efficient Cabinet Table Saw Dust Collection setup keeps internal parts clean, allowing the saw to operate smoothly and maintain consistent cutting accuracy.

Dust Collection Under tablesaw blade Improves Accuracy

Most debris is generated directly below the blade. Without effective Dust Collection Under tablesaw blade, sawdust can accumulate around the cut line, reducing visibility and affecting precision. Capturing dust at the source helps produce cleaner, more accurate cuts.

Dust Collection Must for table saw Safety and Cleanliness

Loose dust on the workshop floor increases the risk of slipping and creates unnecessary cleanup work. A reliable Dust Collection Must for table saw solution keeps the workspace organized, reduces cleanup time, and supports safer movement around the machine.

Tackling Table Saw Dust Collection for Long-Term Efficiency

Consistently addressing dust problems prevents wear on tools and reduces maintenance costs. By Tackling Table Saw Dust Collection early, woodworkers protect both their equipment and their health while maintaining a professional-quality workspace.

Proper dust control is not optional; it is a critical part of responsible and efficient table saw operation.

Understanding How Table Saw Dust Is Generated

Managing dust from table saw During Cutting

When a table saw blade spins at high speed, it breaks wood fibers into fine particles and larger chips. These particles are thrown in multiple directions depending on blade height, cutting depth, and wood type. Without proper control, this debris spreads quickly across the workspace, making managing dust from table saw a constant challenge.

Dust Collection Under tablesaw blade: The Primary Source

The majority of debris is produced beneath the blade as material exits the cut. If Dust Collection Under tablesaw blade is not addressed, sawdust accumulates inside the saw base or falls directly onto the floor. Capturing dust at this point is essential for keeping internal components clean and preventing buildup.

Table saw dust collection guard and Above-Blade Dust

Not all dust travels downward. A significant amount is projected upward and forward, especially during rip cuts. Using a table saw dust collection guard helps capture airborne particles before they spread, improving visibility and reducing fine dust in the air.

Cabinet Table Saw Dust Collection vs Open Designs

Enclosed saw cabinets naturally direct debris toward a collection port, making Cabinet Table Saw Dust Collection more efficient. Open-base or contractor-style saws allow dust to escape freely, which is why they often require additional solutions such as collection bags or enclosures.

Table saw dust collection bag and Passive Control

For saws without built-in ports, a table saw dust collection bag provides basic containment. While not as effective as powered systems, it helps reduce loose debris and prevents dust from scattering uncontrollably.

Understanding how and where dust is created allows woodworkers to choose better collection methods and build a cleaner, safer workspace from the start.

Types of Table Saw Dust Collection Systems

Cabinet Table Saw Dust Collection Systems

Cabinet-style saws are designed with enclosed bases that naturally guide debris toward a dust port. Cabinet Table Saw Dust Collection systems are among the most efficient options because the sealed structure improves airflow and minimizes dust escape. These systems work best when connected to a dedicated dust extractor or central collection unit.

Table Saw Dust Collector for Workshop Setups

A standalone Table Saw Dust Collector is commonly used in small to mid-sized workshops. These units provide strong suction and can handle large volumes of debris. When paired with proper ducting, they significantly reduce cleanup time and improve overall shop air quality.

Table Saw Dust Collection KIT Solutions

For users looking for an all-in-one option, a table saw dust collection KIT offers hoses, fittings, and ports designed to work together. These kits simplify installation and are ideal for upgrading saws that lack factory-installed dust control features.

Tablesaw Dust Collector Adopter and Fittings

Different saws and collectors often use mismatched port sizes. A tablesaw dust collector adopter allows secure connections between hoses and dust ports, ensuring consistent airflow. Proper adapters prevent leaks that reduce collection efficiency.

Table Saw Dust Collection DIY Options

Budget-conscious woodworkers often choose table saw dust collection DIY solutions. These setups may include homemade enclosures, modified ports, or shop vac connections. While DIY systems require careful planning, they can be effective when designed to capture dust near the blade and base.

Table Saw Dust Collection Bag for Basic Control

A table saw dust collection bag is a simple option for saws without powered extraction. It captures larger debris and helps limit dust spread, making it useful for light-duty or mobile workspaces.

Each system has its strengths, and choosing the right one depends on saw design, workspace size, and cutting volume.

Key Components of an Effective Table Saw Dust Collection Setup

Dust Collection Under tablesaw blade as the Core Element

The most critical part of any setup is capturing debris where it is created. Dust Collection Under tablesaw blade prevents sawdust from building up inside the saw base and spreading across the floor. A well-positioned lower dust port ensures chips and fine particles are pulled away immediately after the cut.

Table saw dust collection guard for Above-Blade Control

Not all dust moves downward. Fine particles are often thrown upward toward the operator. A table saw dust collection guard captures this airborne dust at the source, improving visibility and reducing inhalation risks during cutting operations.

Tablesaw dust collection arm for Flexible Capture

A tablesaw dust collection arm supports overhead guards and allows adjustable positioning above the blade. This flexibility helps maintain consistent airflow regardless of material size or cutting angle, making it especially useful in active workshops.

Tablesaw dust collector adopter and Sealed Connections

Air leaks significantly reduce efficiency. A properly fitted tablesaw dust collector adopter ensures hoses and ports connect securely, maintaining strong suction. Tight seals are essential for keeping airflow focused on debris capture rather than escaping gaps.

Table Saw Dust Collection KIT for System Integration

A table saw dust collection KIT combines hoses, adapters, ports, and fittings into one coordinated solution. These kits simplify installation and help users achieve balanced airflow without trial-and-error assembly.

Table saw dust collection bag for Containment

For saws without built-in extraction ports, a table saw dust collection bag helps contain loose debris. While basic, it reduces scattered dust and supports cleaner operation in portable or limited-space environments.

Improving Table Saw Dust Collection Through Airflow Management

Proper hose diameter, smooth interior surfaces, and minimal bends all contribute to Improving Table Saw Dust Collection. Balanced airflow ensures dust is removed efficiently without clogging or loss of suction.

An effective setup relies on combining these components to control dust both above and below the blade, creating a safer and cleaner working environment.

Improving Table Saw Dust Collection Performance

Improving Table Saw Dust Collection with Proper Airflow

Strong airflow is essential for effective dust control. Using the correct hose diameter and keeping duct runs as short as possible helps maintain suction. Smooth, sealed connections prevent air leaks and ensure debris is carried directly into the collection system instead of escaping into the workspace.

Tablesaw dust collection ideas for Better Results

Simple upgrades can make a noticeable difference. Adding internal baffles, sealing gaps in the saw cabinet, or enclosing open bases are practical tablesaw dust collection ideas that help direct debris toward the collection port and reduce dust loss.

Tablesaw dust collection arm for Above-Blade Efficiency

Fine particles released above the blade often remain airborne. A tablesaw dust collection arm paired with an overhead guard captures this dust before it spreads, improving visibility and protecting the operator from inhaling harmful particles.

Managing dust from table saw with Combined Collection

Relying on a single collection point is rarely enough. Combining lower extraction with above-blade capture improves overall performance. This approach makes managing dust from table saw more consistent, especially during long cutting sessions or high-volume work.

Dust Collection Must for table saw Maintenance Practices

Regular maintenance is a Dust Collection Must for table saw systems. Cleaning filters, emptying collection bags, and checking for blockages help maintain consistent airflow and prevent reduced performance over time.

Tackling Table Saw Dust Collection with Small Adjustments

Minor adjustments such as repositioning hoses, improving seals, or upgrading fittings can greatly enhance efficiency. Tackling Table Saw Dust Collection does not always require major upgrades; thoughtful refinements often deliver strong results.

Consistent airflow management and smart enhancements are the key to achieving reliable and long-lasting dust control performance.

Tablesaw Dust Collection Ideas for Small and Home Workshops

Tablesaw dust collection ideas for Limited Space

Small workshops require solutions that save space without sacrificing performance. Compact setups that use wall-mounted collectors or mobile units are effective tablesaw dust collection ideas for controlling debris while keeping the work area open and organized.

Table saw dust collection DIY Solutions

Many home woodworkers rely on table saw dust collection DIY methods to reduce costs. Simple enclosures around the saw base, modified dust ports, or custom hoods can significantly improve debris capture when designed to direct airflow toward a single collection point.

Table saw dust collection bag for Portable Saws

For jobsite or portable saws, a table saw dust collection bag offers a practical way to contain larger debris. While basic, it helps prevent dust from spreading across small work areas and reduces cleanup time.

Tablesaw dust collector adopter for Flexible Connections

Different tools often require different hose sizes. A tablesaw dust collector adopter allows small workshops to connect multiple tools to one collector without constant reconfiguration, improving overall efficiency.

Managing dust from table saw in Home Environments

Home workshops often share space with other activities, making dust control even more important. Proper managing dust from table saw protects nearby surfaces, reduces airborne particles, and keeps the area cleaner and safer for daily use.

Dust Collection Must for table saw in Small Shops

Even in compact spaces, effective dust control is a Dust Collection Must for table saw operation. Thoughtful planning and simple upgrades can deliver reliable performance without requiring large or expensive equipment.

Smart, space-conscious solutions allow small and home workshops to maintain clean and efficient cutting environments.

Must-Have Accessories for Better Dust Control

Table Saw Dust Collection Guard for Operator Protection

A table saw dust collection guard is essential for capturing fine particles thrown above the blade. It improves visibility during cuts and reduces airborne dust that can be inhaled, making it a key safety and cleanliness accessory.

Tablesaw dust collection arm for Adjustable Coverage

A tablesaw dust collection arm supports overhead guards and allows flexible positioning. This accessory helps maintain effective dust capture across different cutting angles and material sizes.

Table Saw Dust Collection KIT for Easy Upgrades

A table saw dust collection KIT provides a complete set of hoses, fittings, and connectors designed to work together. These kits simplify installation and help users achieve balanced airflow without guesswork.

Tablesaw dust collector adopter for Secure Connections

Proper airflow depends on tight connections. A tablesaw dust collector adopter ensures hoses fit correctly between tools and collectors, preventing air leaks that reduce efficiency.

Table saw dust collection bag for Simple Containment

For saws without powered extraction, a table saw dust collection bag helps contain larger debris. It is especially useful for portable or jobsite saws where space and power are limited.

Common Mistakes to Avoid

Ignoring Dust Collection Under tablesaw blade

Failing to address Dust Collection Under tablesaw blade allows debris to accumulate inside the saw and on the floor. This reduces efficiency and increases cleanup time.

Poor Managing dust from table saw Planning

Relying on a single collection point often leads to missed dust sources. Effective managing dust from table saw requires both below-blade and above-blade solutions working together.

Overlooking Cabinet Table Saw Dust Collection Sealing

Gaps and leaks inside the cabinet weaken airflow. Even strong collectors perform poorly if Cabinet Table Saw Dust Collection systems are not properly sealed.

Skipping Dust Collection Must for table saw Maintenance

Clogged filters and full bags reduce suction. Regular cleaning is a Dust Collection Must for table saw systems to remain effective over time.

Using Incorrect Fittings Instead of a Tablesaw dust collector adopter

Loose or mismatched hose connections reduce performance. Using the correct tablesaw dust collector adopter prevents airflow loss and improves overall efficiency.

Final Thoughts: Tackling Table Saw Dust Collection the Right Way

Tackling Table Saw Dust Collection with the Right Approach

Effective dust control starts with understanding how debris is created and choosing the right combination of tools and accessories. Tackling Table Saw Dust Collection early helps protect health, improve accuracy, and extend equipment life.

Improving Table Saw Dust Collection Through Smart Choices

Balanced airflow, sealed connections, and proper accessories all contribute to Improving Table Saw Dust Collection. Small upgrades often deliver significant results when thoughtfully applied.

Dust Collection Must for table saw Long-Term Success

Consistent attention to dust control is a Dust Collection Must for table saw users at every level. Whether in a home shop or professional workspace, proper systems lead to cleaner, safer, and more efficient woodworking.

By combining proven methods with the right accessories, woodworkers can maintain a controlled and productive cutting environment for years to come.

Conclusion

In conclusion, tablesaw dust collection is essential for maintaining a safe, clean, and efficient woodworking environment. Proper dust control protects your health, improves cutting accuracy, and prolongs the life of your equipment. By combining the right collection systems, accessories, and maintenance practices, woodworkers can effectively capture debris both above and below the blade. Whether you are using a cabinet table saw, a portable unit, or DIY solutions, focusing on tablesaw dust collection ensures a cleaner workspace, safer operation, and better overall performance. Investing in effective dust management is not just about cleanliness—it’s a crucial part of responsible woodworking.

Top Five FAQs

Q.1 Why are dust collectors important?

Dust collectors are important because they capture fine dust and debris at the source, keeping the air clean and reducing cleanup time. They help protect tools from dust buildup, improve work accuracy, and create a safer and more organized workspace.

Q.2 What is the best dust collection setup for a table saw?

The best setup combines below-blade dust extraction with an overhead guard system, sealed connections, and proper airflow to capture dust at the source.

Q.3 Can I use a shop vacuum for table saw dust collection?

Yes, a shop vacuum can be used for light-duty table saw dust collection, especially in small workshops, but it may not provide enough airflow for heavy or continuous cutting.

Q.4 Is it healthy to breathe in sawdust?

Breathing in sawdust is not healthy. Fine wood particles can irritate the lungs, trigger allergies, and cause long-term respiratory problems with repeated exposure. Proper dust control and ventilation help reduce these health risks.

Q.5 What are the common uses for sawdust?

Sawdust is commonly used for composting, animal bedding, spill absorption, mulch, and making wood pellets or particleboard. It is also used in craft projects and as a fuel source in some heating systems.