Introduction

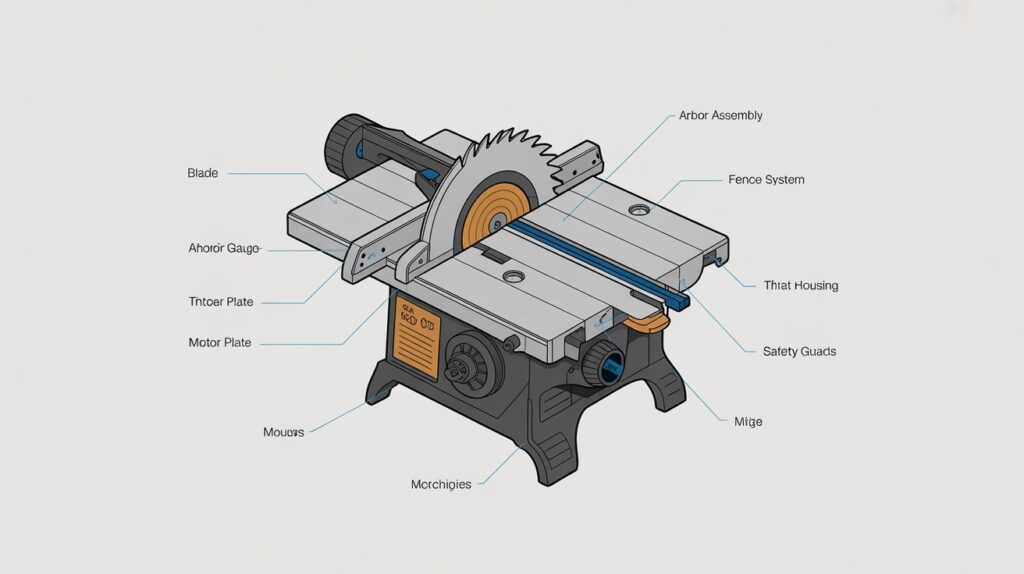

Table saw parts form the backbone of every successful woodworking project. Knowing the function and maintenance of each component—from the blade and arbor to the fence system and safety features—ensures precise cuts, safer operation, and longer tool life. This guide will break down all essential table saw parts, explain their purpose, and provide tips on proper use and maintenance, helping woodworkers of all skill levels work efficiently and safely.

Table of Contents

Table Saw Blade and Its Types

Role of the Table Saw Blade

The blade is one of the most important table saw parts because it directly affects cutting quality and safety. Among all table saw components, the blade is responsible for making clean and accurate cuts in wood and other materials. Choosing the correct blade improves cutting accuracy, reduces material waste, and supports smooth operation of woodworking tools.

Basic Structure of a Table Saw Blade

A table saw blade consists of a circular steel disc with cutting teeth around the edge. The center hole fits onto the table saw arbor assembly, allowing power transmission from the motor to the blade. Tooth design, blade diameter, and thickness all influence how the blade performs during rip cuts and crosscuts.

Common Table Saw Blade Types

Different table saw blade types are designed for specific cutting tasks. Selecting the right blade helps protect other table saw parts and ensures proper saw calibration.

Rip Cut Blades

Rip cut blades are designed for cutting along the wood grain. They have fewer teeth and larger spaces between them, allowing fast material removal. These blades reduce strain on table saw motor parts and improve efficiency during long rip cuts.

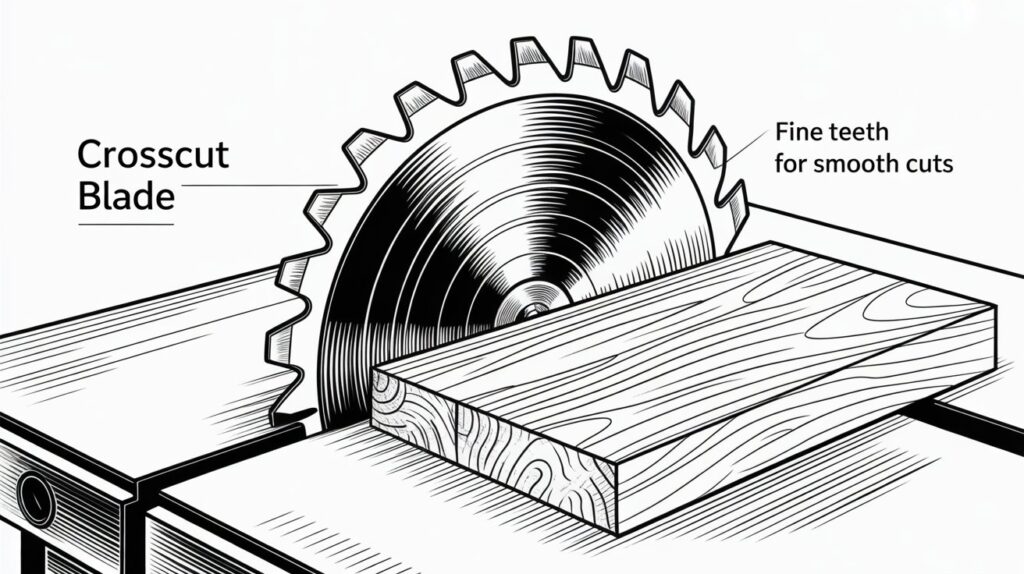

Crosscut Blades

Crosscut blades are specifically made for cutting wood perpendicular to the grain. They feature more teeth with finer edges, which results in smoother cuts. These blades support high cutting accuracy when paired with a properly aligned table saw fence system or miter gauge.

Combination Blades

Combination blades are versatile table saw parts suitable for both rip cuts and crosscuts. They balance speed and finish quality, making them a popular choice for general woodworking tasks.

Dado Blades

Dado blades are specialized table saw components used to cut wide grooves and slots. They are commonly used in cabinetry and furniture work. Proper installation and alignment are important to maintain safety and protect table saw safety parts.

Blade Selection and Cutting Accuracy

Choosing the correct blade improves blade alignment and overall performance. Using the wrong blade can cause vibration, rough edges, and stress on other table saw maintenance parts. Proper blade selection also supports kickback prevention and smoother material feeding.

Maintenance and Safety Considerations

Regular inspection of the blade is essential for safe operation. Dull or damaged blades should be replaced with quality table saw replacement parts to maintain cutting efficiency. Keeping the blade clean also improves dust control and extends the life of related table saw components.

Importance of the Blade in Woodworking Tools

Within all woodworking tools, the table saw relies heavily on blade quality. A well-chosen blade enhances productivity, supports accurate cuts, and protects surrounding table saw parts from unnecessary wear. Understanding blade types helps users achieve consistent and professional results.

Arbor, Arbor Nut, and Flange

Purpose of the Arbor in Table Saw Parts

The arbor is a central component among all table saw parts because it supports and rotates the blade. It is a metal shaft connected to the motor that transfers power directly to the blade. Proper function of the arbor is essential for stable cutting, smooth operation, and accurate results when using woodworking tools.

Understanding the Arbor Assembly

The table saw arbor assembly includes the arbor shaft, arbor nut, and flange. These table saw components work together to hold the blade firmly in place. When correctly assembled, the arbor keeps the blade aligned and reduces vibration during rip cuts and crosscuts. A well-aligned arbor also protects other table saw maintenance parts from excessive wear.

Role of the Arbor Nut

The arbor nut secures the blade onto the arbor shaft. It ensures that the blade remains tightly fastened during operation. Among important table saw parts, the arbor nut plays a key role in safety and cutting accuracy. A loose arbor nut can cause blade wobble, uneven cuts, and increased risk of kickback.

Function of the Flange

The flange is a flat metal disc placed between the blade and the arbor nut. Its purpose is to evenly distribute pressure across the blade surface. This helps maintain blade alignment and prevents damage to the blade. Proper flange positioning improves saw calibration and supports consistent cutting performance.

How Arbor Components Affect Cutting Accuracy

Accurate cutting depends on the stability of the arbor assembly. When the arbor, nut, and flange are correctly installed, the blade rotates smoothly and maintains a straight cutting path. This stability improves cutting accuracy and reduces stress on table saw motor parts and the table saw fence system.

Safety and Maintenance Considerations

Regular inspection of the arbor assembly is important for safe operation. Worn threads, damaged flanges, or loose arbor nuts should be replaced with quality table saw replacement parts. Keeping these table saw safety parts in proper condition supports kickback prevention and long-term reliability.

Importance of the Arbor Assembly in Woodworking

Among all parts of a table saw, the arbor assembly directly influences blade performance and user safety. A well-maintained arbor system ensures efficient power transmission, smooth cuts, and dependable operation in all types of woodworking projects.

Rip Fence System

Role of the Rip Fence in Table Saw Parts

The rip fence is one of the most important table saw parts because it controls the width and straightness of a cut. It runs parallel to the blade and guides the workpiece during rip cuts. A properly adjusted rip fence improves cutting accuracy and helps maintain consistent results when using woodworking tools.

How the Rip Fence System Works

The table saw fence system locks into position along the tabletop, allowing the user to set an exact cutting width. This system keeps the material steady as it moves through the blade. Among essential table saw components, the rip fence plays a key role in blade alignment and saw calibration.

Types of Rip Fence Systems

Different table saw parts include various fence designs depending on the saw model.

Standard Rip Fence

This fence slides along rails and locks at the front of the table. It is common on portable and contractor saws and offers basic control for general woodworking tasks.

T-Square Rip Fence

The T-square design provides stronger locking at both the front and rear of the table. This type improves stability and reduces fence movement, leading to higher cutting accuracy.

Importance of Fence Alignment

Proper fence alignment is critical for safe and accurate cutting. A misaligned fence can cause binding and increase the risk of kickback. Regular adjustment of the rip fence helps protect table saw safety parts and ensures smooth material flow during cutting.

Maintenance and Safety Considerations

The rip fence should be kept clean and free of damage. Worn locking mechanisms or bent rails should be replaced with quality table saw replacement parts. Regular inspection of this system supports safe operation and extends the life of other table saw maintenance parts.

Contribution to Woodworking Efficiency

A stable rip fence system improves productivity by allowing repeatable cuts with minimal setup time. When combined with effective table saw parts such as a flat tabletop and a sharp blade, the fence system enhances overall cutting performance and accuracy.

Miter Gauge and Angle Controls

Function of the Miter Gauge in Table Saw Parts

The miter gauge is a key component among table saw parts that controls angled and crosscuts. It fits into the miter slot on the tabletop and guides the workpiece at a set angle as it moves toward the blade. This component is essential for achieving precise cuts in woodworking tools.

How the Miter Gauge Works

The miter gauge consists of a guide bar, an adjustable head, and angle markings. These table saw components allow users to set accurate angles for cutting. When properly adjusted, the miter gauge supports smooth movement and helps maintain cutting accuracy during crosscuts.

Understanding Angle Controls

Angle controls allow the user to adjust the miter gauge to common cutting angles such as 45 and 90 degrees. Accurate angle settings improve saw calibration and ensure consistent results. Among important parts of a table saw, angle controls play a vital role in producing clean and precise cuts.

Importance of Miter Gauge Accuracy

An accurately aligned miter gauge reduces blade binding and helps prevent kickback. Poor alignment can affect blade alignment and place stress on other table saw safety parts. Routine inspections help maintain safe use and consistent performance.

Maintenance and Adjustment Tips

Keeping the miter gauge clean and properly fitted to the miter slot is essential. Worn or loose parts should be replaced with quality table saw replacement parts. Routine inspection of this system supports long-term reliability and protects other table saw maintenance parts.

Role in Woodworking Efficiency

The miter gauge improves workflow by allowing repeatable angled cuts with minimal setup. When combined with other well-maintained table saw parts, it enhances productivity and ensures professional-quality results in woodworking projects.

Tabletop and Extension Wings

Importance of the Tabletop in Table Saw Parts

The tabletop is a foundational element among table saw parts because it supports the workpiece during cutting. A flat and stable tabletop ensures smooth material movement and accurate results. As one of the primary table saw components, it directly affects cutting accuracy and overall performance of woodworking tools.

Materials Used in Table Saw Tabletops

Tabletops are commonly made from cast iron, aluminum, or steel. Cast iron surfaces provide maximum stability and vibration control, while aluminum tabletops offer lighter weight and portability. Choosing the right material helps maintain blade alignment and protects other table saw maintenance parts from unnecessary strain.

Role of Extension Wings

Extension wings increase the surface area of the tabletop, allowing better support for large or wide materials. These table saw parts attach to either side of the main table and improve balance during rip cuts. Properly installed extension wings enhance control and reduce the risk of material tipping.

How Tabletop Design Affects Cutting Accuracy

A level and smooth tabletop supports consistent feeding of the workpiece. Any uneven surface can affect saw calibration and lead to inaccurate cuts. Regular inspection of the tabletop and extension wings helps maintain precision and supports reliable operation of the table saw fence system.

Maintenance and Safety Considerations

Keeping the tabletop clean and free from rust is essential for safe use. Damaged or warped surfaces should be repaired or replaced with quality table saw replacement parts. Proper care of these surfaces also improves dust control and reduces wear on table saw safety parts.

Contribution to Woodworking Efficiency

A well-designed tabletop with extension wings improves workflow by providing a stable cutting platform. When combined with other properly aligned table saw parts, it supports efficient cutting and consistent results across a wide range of woodworking projects.

Riving Knife, Splitter, and Kickback Prevention Parts

Importance of Riving Knife and Splitter in Table Saw Parts

The riving knife and splitter are critical table saw parts designed to enhance safety during cutting operations. They prevent the workpiece from pinching the blade, which is one of the main causes of kickback. Proper use of these table saw components ensures safer operation and protects both the operator and other table saw maintenance parts.

Function of the Riving Knife

The riving knife is a thin, vertical metal piece located behind the blade. It moves along with the blade during height adjustments and helps maintain consistent spacing between the cut sections of the material. Unlike older splitters, the riving knife does not need to be removed for angled cuts, which improves convenience and safety.

Role of the Splitter

The splitter is a fixed or removable vertical component placed behind the blade. Its primary function is to prevent the wood from closing in on the blade, which can cause binding and sudden kickback. Among essential table saw safety parts, the splitter works alongside the riving knife and blade guard to protect the user during rip cuts.

Kickback Prevention Parts

Kickback prevention parts include the riving knife, splitter, anti-kickback pawls, and blade guards. These table saw components work together to control material movement and reduce the risk of the workpiece being thrown toward the operator. Proper installation and maintenance of these parts are crucial for safe woodworking practices.

Maintenance and Safety Tips

Regular inspection of the riving knife, splitter, and associated table saw safety parts ensures reliable operation. Bent or damaged components should be replaced with quality table saw replacement parts. Keeping these parts aligned with the blade improves cutting accuracy and protects other table saw maintenance parts from damage.

Contribution to Woodworking Efficiency

Using a properly aligned riving knife and splitter improves workflow by reducing interruptions caused by material binding or kickback incidents. When combined with other table saw parts, these safety components support precise cuts and enhance overall efficiency in woodworking projects.

Blade Guard and Other Safety Table Saw Parts

Importance of Blade Guard in Table Saw Parts

The blade guard is a critical component among table saw parts that protects the user from direct contact with the spinning blade. It covers the cutting area and reduces the risk of injuries while allowing wood to pass through smoothly. Proper use of the blade guard is essential for maintaining safety and protecting other table saw maintenance parts.

Function of the Blade Guard

The blade guard acts as a physical barrier between the operator and the blade. It prevents accidental hand contact and helps guide wood during cuts. Along with the riving knife and splitter, it forms part of the essential table saw safety parts that control material movement and minimize the risk of kickback.

Other Key Safety Table Saw Parts

Anti-Kickback Pawls

Anti-kickback pawls are small, toothed components that allow the material to move forward while preventing it from being thrown backward. These table saw components work with the blade guard and riving knife to enhance safety during rip cuts.

Push Sticks and Push Blocks

Push sticks and push blocks are safety accessories used to move small or narrow workpieces through the blade. They are considered part of table saw safety parts and help maintain control, reducing the risk of injury.

Safety Switches

Many modern table saws include magnetic or safety switches that prevent accidental startup. These switches protect both the operator and internal table saw components like the motor and arbor assembly.

Maintenance of Safety Parts

Regular inspection and maintenance of the blade guard and other table saw safety parts are critical for reliable operation. Worn or damaged parts should be replaced with quality table saw replacement parts to maintain cutting accuracy and safe performance. Proper alignment ensures that the guard, riving knife, and pawls work together effectively.

Impact on Woodworking Efficiency

Using well-maintained safety components increases efficiency by allowing the operator to focus on accurate cuts rather than injury prevention. Integrated table saw parts such as the blade guard, anti-kickback pawls, and push sticks contribute to smoother workflow and safer woodworking practices.

Motor, Drive Belt, and Power System

Role of the Motor in Table Saw Parts

The motor is one of the most essential table saw parts, providing the power required to rotate the blade and perform cutting operations. It converts electrical energy into mechanical motion, driving the arbor and blade to achieve precise rip cuts and crosscuts. A properly functioning motor ensures smooth operation and reduces strain on other table saw maintenance parts.

Understanding the Drive Belt

The drive belt connects the motor to the arbor, transmitting power efficiently to the blade. Among critical table saw components, the drive belt ensures consistent blade speed and reduces vibration. A worn or loose drive belt can decrease cutting accuracy and increase stress on the table saw fence system and motor parts.

Power System Components

The power system of a table saw includes the motor, drive belt, pulleys, and electrical switches. Together, these table saw components regulate energy flow, control blade rotation, and support the overall performance of the saw. Proper calibration and alignment of the power system are essential for safe and efficient operation.

Maintenance of Motor and Drive Components

Regular maintenance of the motor, drive belt, and related table saw maintenance parts ensures long-term reliability. Inspecting the belt for wear, checking pulley alignment, and keeping the motor clean helps prevent overheating and improves cutting accuracy. Damaged parts should be replaced with quality table saw replacement parts to maintain safety and efficiency.

Impact on Cutting Accuracy and Safety

A well-maintained motor and drive system directly affect the performance of other table saw parts, including the arbor assembly, blade, and fence system. Consistent power delivery reduces vibration, enhances blade alignment, and supports safe operation by minimizing kickback risks.

Contribution to Woodworking Efficiency

Efficient power transmission from the motor through the drive belt ensures smooth and continuous cutting. When combined with other properly maintained table saw parts, the motor and drive system improve productivity and provide precise results across all types of woodworking projects.

Motor, Drive Belt, and Power System

Role of the Motor in Table Saw Parts

The motor is one of the most essential table saw parts, providing the power required to rotate the blade and perform cutting operations. It converts electrical energy into mechanical motion, driving the arbor and blade to achieve precise rip cuts and crosscuts. A properly functioning motor ensures smooth operation and reduces strain on other table saw maintenance parts.

Understanding the Drive Belt

The drive belt connects the motor to the arbor, transmitting power efficiently to the blade. Among critical table saw components, the drive belt ensures consistent blade speed and reduces vibration. A worn or loose drive belt can decrease cutting accuracy and increase stress on the table saw fence system and motor parts.

Power System Components

The power system of a table saw includes the motor, drive belt, pulleys, and electrical switches. Together, these table saw components regulate energy flow, control blade rotation, and support the overall performance of the saw. Proper calibration and alignment of the power system are essential for safe and efficient operation.

Maintenance of Motor and Drive Components

Regular maintenance of the motor, drive belt, and related table saw maintenance parts ensures long-term reliability. Inspecting the belt for wear, checking pulley alignment, and keeping the motor clean helps prevent overheating and improves cutting accuracy. Damaged parts should be replaced with quality table saw replacement parts to maintain safety and efficiency.

Impact on Cutting Accuracy and Safety

A well-maintained motor and drive system directly affect the performance of other table saw parts, including the arbor assembly, blade, and fence system. Consistent power delivery reduces vibration, enhances blade alignment, and supports safe operation by minimizing kickback risks.

Contribution to Woodworking Efficiency

Efficient power transmission from the motor through the drive belt ensures smooth and continuous cutting. When combined with other properly maintained table saw parts, the motor and drive system improve productivity and provide precise results across all types of woodworking projects.

Dust Collection and Maintenance Components

Importance of Dust Collection in Table Saw Parts

The dust collection system is an essential element among table saw parts, designed to remove sawdust and debris generated during cutting. Effective dust control improves safety, maintains clean work surfaces, and prevents excessive wear on other table saw maintenance parts. It also supports better cutting accuracy and extends the lifespan of the saw.

Components of a Table Saw Dust Collection System

A typical dust collection system includes the dust port, hoses, and vacuum or collector unit. These table saw components work together to capture airborne particles and prevent them from accumulating around the blade and motor. A well-maintained dust collection system reduces the risk of clogging and protects table saw safety parts.

Role of Maintenance Components

Regular maintenance is critical for all table saw parts to ensure smooth operation. Key maintenance components include lubricated bearings, clean pulleys, and blade alignment tools. Proper upkeep prevents binding, vibration, and inaccurate cuts, protecting the motor, arbor assembly, and other table saw components from damage.

Maintenance Tips for Optimal Performance

- Clean dust ports and hoses regularly to maintain airflow.

- Inspect bearings and moving parts for wear and lubricate as needed.

- Check blade alignment and fence calibration to maintain cutting accuracy.

- Replace worn or damaged parts with quality table saw replacement parts.

Routine maintenance ensures safety, efficiency, and consistent performance across all woodworking projects.

Impact on Safety and Efficiency

A functional dust collection system reduces airborne dust, improving respiratory safety for the operator. Combined with other table saw safety parts, proper maintenance minimizes kickback and blade binding risks. Clean and well-maintained table saw parts also improve workflow, allowing faster and more accurate cuts.

Conclusion on Dust Collection and Maintenance

Dust collection and maintenance components play a vital role in protecting both the operator and the saw. By keeping the system clean and parts properly maintained, woodworking efficiency and safety are significantly enhanced. These components ensure that all other table saw parts function reliably and last longer.

Conclusion

Understanding table saw parts is crucial for both safety and performance in woodworking. From the blade and arbor assembly to safety components like the riving knife, splitter, and blade guard, each part plays a specific role in ensuring accurate cuts and smooth operation. Proper maintenance of dust collection, motor, and drive components further extends the life of the saw and improves efficiency. By familiarizing yourself with these table saw components and keeping them in optimal condition, you can achieve precise results, reduce the risk of accidents, and maximize the overall performance of your table saw.

FAQs

Q.1 What are the basic parts of a table saw?

The basic table saw parts include the blade, arbor assembly, rip fence, miter gauge, tabletop, motor, blade guard, riving knife, and dust collection port. These parts work together to provide accurate cuts and safe operation.

Q.2 What is the arbor on a table saw?

The arbor is one of the most important table saw parts. It is a metal shaft that holds the blade in place and connects it to the motor. The arbor allows the blade to rotate smoothly and stay properly aligned during cutting.

Q.3 Why is it important to know table saw parts?

Knowing table saw parts helps users operate the saw safely, maintain it properly, and achieve precise cuts. Understanding each component reduces the risk of accidents and improves woodworking efficiency.

Q.4 What are the different types of table saw blades?

Common table saw parts include different blade types such as rip cut blades, crosscut blades, combination blades, and dado blades. Each blade is designed for specific cutting tasks and materials.

Q.5 Can you rip a 2×4 with a table saw?

Yes, a table saw can easily rip a 2×4. Using the proper blade and correctly adjusted table saw parts, such as the rip fence and blade height, ensures clean and controlled rip cuts.