Introduction

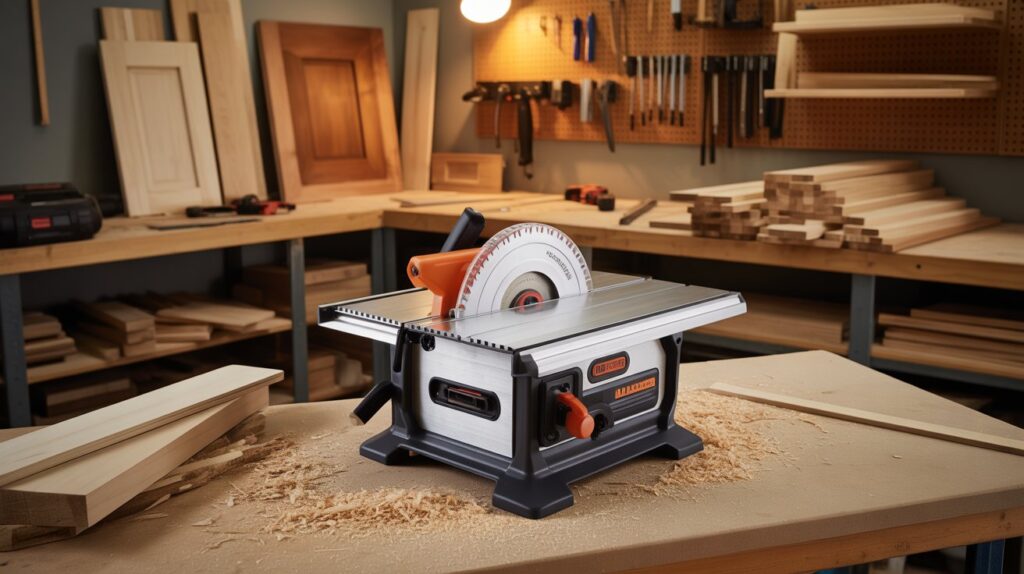

A benchtop table saw is a versatile and compact woodworking tool designed for precision, portability, and convenience. Perfect for beginners, DIY enthusiasts, and professionals, it allows for cutting wood accurately in small workshops, garages, or home renovation projects without the need for large, stationary equipment.

Table of Contents

What Is a Benchtop Table Saw?

A benchtop table saw is a compact and portable woodworking machine designed to sit on top of a workbench or flat surface. It uses a circular blade mounted beneath a small table to make straight, accurate cuts in wood and sheet materials. Compared to larger table saws, it is lighter in weight, easier to move, and simpler to set up, which makes it well suited for home workshops and limited spaces.

This type of saw is commonly powered by a direct-drive motor that delivers enough speed and cutting ability for tasks such as rip cuts, crosscuts, and basic woodworking projects. A benchtop table saw is especially useful for beginners and DIY users who want reliable performance without the cost, size, or complexity of professional-grade equipment.

Key Benefits of a Benchtop Table Saw

Portable Table Saw for Flexible Workspaces

One of the biggest advantages is portability. A portable table saw is easy to move, set up, and store, making it ideal for garages, basements, and temporary job sites. Its compact size allows users to work efficiently without needing a permanent workshop.

Compact Table Saw for Small Workshops

A compact table saw is designed for users with limited space. It fits well in a table saw for home workshop setup and can be placed on standard benches or tables. This makes it a practical solution for hobbyists and homeowners working in tight areas.

Affordable Table Saw for Beginners and DIY Users

For those starting out, an affordable table saw offers excellent value. It provides reliable performance for woodworking tools for beginners and supports a wide range of DIY projects without the high cost of larger machines.

Accurate Cutting and Reliable Performance

Despite its size, this tool supports cutting wood accurately for tasks such as rip cuts and crosscuts. Features like a stable fence system, proper alignment, and consistent motor power and blade speed help users achieve clean and precise results.

Built-In Safety and Ease of Use

Modern models include essential safety features on table saws such as a blade guard and fence system. These features make it safer for beginners while still meeting the needs of experienced users handling portable woodworking equipment for everyday tasks.

Who Should Buy a Benchtop Table Saw

Small Table Saw for Beginners

A small table saw for beginners is ideal for those just starting in woodworking. It allows users to practice cutting wood accurately and gain confidence with woodworking tools for beginners without investing in large or expensive equipment. Its simplicity and ease of use make it perfect for learning basic techniques.

Benchtop Table Saw for DIY Projects

DIY enthusiasts working on home improvement tasks will benefit from a benchtop table saw for DIY projects. It is suitable for home renovation projects like building shelves, cabinets, and furniture, where precision and portability are important.

Portable Table Saw for Professionals

Even experienced woodworkers and professionals can use a portable table saw as a convenient secondary tool. Its lightweight table saw design makes it easy to transport between job sites, providing flexibility for small to medium tasks without compromising rip cuts and crosscuts quality.

Compact Table Saw for Limited Spaces

Anyone with limited workshop space will find a compact table saw practical. It fits on a table saw for home workshop setup and can be stored easily when not in use. Its portability ensures that even users in small apartments or garages can perform precise woodworking efficiently.

Important Features to Look for When Buying a Benchtop Table Saw

Motor Power and Blade Speed

A reliable motor power and blade speed are essential for smooth and accurate cutting wood accurately. Higher-powered motors handle thicker or harder materials more efficiently, while consistent blade speed ensures clean rip cuts and crosscuts without burning or chipping the wood.

Rip Capacity and Cutting Depth

Check the rip capacity and cutting depth to ensure the saw can handle your typical projects. A benchtop table saw for DIY projects should provide enough width for ripping larger boards and adequate depth for cutting plywood and hardwood safely.

Fence Quality and Accuracy

A precise fence is critical for straight and consistent cuts. Look for a fence system that is stable, easy to adjust, and locks securely in place. This feature improves performance for both woodworking tools for beginners and advanced users.

Safety Features on Table Saws

Modern saws include important safety features on table saws such as a blade guard and anti-kickback pawls. These prevent accidents and make it safer for DIY projects while still maintaining precision and control.

Build Quality and Durability

Even as a lightweight table saw, durability matters. Look for a sturdy table, quality materials, and well-built components to ensure long-term use. A portable woodworking equipment that is strong and stable provides better performance and reduces maintenance needs.

Benchtop Table Saw vs Other Types of Table Saws

Benchtop vs Jobsite Table Saw

A benchtop table saw for DIY projects is smaller and more portable than a jobsite table saw, making it ideal for home workshops and limited spaces. While a jobsite table saw often provides higher motor power and blade speed and larger rip capacity, it is heavier and less convenient to move, making the benchtop option better for quick, flexible projects.

Benchtop vs Contractor Table Saw

A contractor table saw is typically more robust, with a larger table surface and heavier construction for professional work. In contrast, a compact table saw is easier to handle and store. For home renovation projects and smaller DIY projects, the portability and simplicity of a benchtop saw outweigh the extra features of a contractor saw.

Pros and Cons Comparison

- Benchtop table saw: Lightweight, portable, affordable, easy to store; limited rip capacity and cutting depth, less suitable for large-scale professional tasks.

- Jobsite/Contractor saws: More powerful, handle larger materials, better durability; less convenient for small spaces, heavier, higher cost.

By understanding these differences, users can select the right saw for their needs, whether it’s cutting wood accurately for small home improvement projects or transporting portable woodworking equipment between sites.

Common Uses of a Benchtop Table Saw

Cutting Plywood and Hardwood

A benchtop table saw for DIY projects excels at cutting wood accurately, including both plywood and hardwood. Its adjustable blade and stable fence system allow for precise rip cuts and crosscuts, making it suitable for furniture components, shelving, and cabinetry.

DIY Furniture Projects

For home renovation projects or custom furniture, a small table saw for beginners provides the accuracy and control needed to shape and size pieces. Whether building tables, chairs, or cabinets, its portable table saw design ensures it can be used in small workshops or garages with ease.

Home Improvement Tasks

From cutting baseboards to trimming panels, a table saw for home workshop is highly useful for general DIY projects. Its motor power and blade speed handle standard home materials, allowing users to complete projects efficiently without relying on larger, stationary saws.

Small Professional Jobs

Even professionals can benefit from a lightweight table saw for on-site tasks where mobility is key. Its portable woodworking equipment design ensures accurate cutting wood accurately in temporary setups or tight spaces, making it a versatile tool for small-scale jobs.

Safety Tips When Using a Benchtop Table Saw

Proper Setup and Positioning

Ensure your benchtop table saw for DIY projects is placed on a stable and level surface before use. Keep the surrounding area clear of clutter to maintain safe working space. Correct setup helps achieve precise rip cuts and crosscuts while reducing the risk of accidents.

Use of Safety Gear

Always wear appropriate protective equipment such as safety glasses, hearing protection, and dust masks. Utilizing safety features on table saws, including blade guard and anti-kickback pawls, is essential for preventing injuries during cutting wood accurately.

Maintain Focus and Control

Avoid distractions and keep hands clear of the blade path. Use push sticks or feather boards when guiding small or narrow pieces through the saw. This ensures safer handling when using portable woodworking equipment.

Regular Inspection and Maintenance

Check the fence system, blade alignment, and motor power and blade speed before each session. Keeping your benchtop table saw for DIY projects in proper working order minimizes the risk of malfunctions that could lead to accidents.

Beginner-Friendly Practices

For woodworking tools for beginners, start with smaller, simpler cuts and gradually progress to more complex tasks. Following these safety practices helps build confidence while working on home renovation projects or DIY projects efficiently and safely.

How to Maintain a Benchtop Table Saw

Cleaning and Blade Care

Regular cleaning is essential for a benchtop table saw for DIY projects to maintain cutting wood accurately. Remove sawdust and debris from the table, blade, and fence system after each use. Sharpen or replace the blade as needed to ensure smooth rip cuts and crosscuts.

Check Fence and Alignment

Inspect the fence system regularly to ensure it is straight and locks securely. Proper alignment keeps cuts precise and prevents material from binding or shifting during home renovation projects and DIY projects.

Lubrication and Mechanical Care

Apply light lubrication to moving parts, such as the blade adjustment mechanism and trunnions. This ensures the motor power and blade speed remain consistent and the portable table saw operates smoothly.

Safe Storage

Store your lightweight table saw in a dry, clean environment to prevent rust and damage. A compact table saw for home workshop setup can be covered or placed in a cabinet when not in use, extending the tool’s lifespan.

Routine Inspection for Longevity

Check all electrical connections, screws, and safety features on a benchtop table saw for DIY projects regularly. Keeping your portable woodworking equipment in optimal condition ensures reliable performance and enhances safety over time.

Final Buying Advice

Prioritize Portability and Size

When selecting a benchtop table saw for DIY projects, consider a portable table saw or compact table saw that fits your workspace. A lightweight design ensures you can move and store it easily, making it ideal for table saw for home workshop setups or small garages.

Focus on Performance and Features

Check motor power and blade speed to ensure the saw can handle your typical materials. A stable fence system and adjustable cutting depth are essential for achieving cutting wood accurately and smooth rip cuts and crosscuts.

Safety and User-Friendliness

Choose a model with built-in safety features on table saws such as a blade guard and anti-kickback pawls. This is especially important for beginners using woodworking tools for beginners or DIY enthusiasts tackling home renovation projects.

Consider Durability and Value

Even for a lightweight table saw, durability matters. Look for sturdy construction and quality materials to ensure long-term use. An affordable table saw that combines portability, performance, and durability offers the best value for both beginners and experienced users.

By balancing affordable table saw options with performance, safety, and portability, users can confidently choose the right tool for their DIY projects, home workshops, or small professional jobs.

Conclusion

A benchtop table saw is an essential tool for anyone looking for precision, portability, and efficiency in woodworking. Whether you are a beginner, DIY enthusiast, or professional, it allows for cutting wood accurately in small workshops, home projects, or on-the-go tasks. Choosing the right model ensures safety, reliability, and long-term performance, making it a valuable addition to any woodworking setup.

FAQs

Q1. What is a benchtop table saw used for?

A benchtop table saw is used for precise cutting of wood and sheet materials. It is ideal for DIY projects, home workshops, furniture building, and small professional tasks.

Q2. Who should buy a benchtop table saw?

Beginners, DIY enthusiasts, and professionals who need a portable table saw for small to medium tasks will benefit most. It’s perfect for limited workshop spaces and home projects.

Q3. How do I choose the best benchtop table saw?

Look for motor power and blade speed, a stable fence system, rip capacity and cutting depth, and safety features such as blade guards. Portability and durability are also important.

Q4. Is a benchtop table saw safe for beginners?

Yes. Modern models include safety features on table saws like blade guards and anti-kickback pawls, making them suitable for beginners learning cutting wood accurately.

Q5. How do I maintain a benchtop table saw?

Keep it clean, regularly check the fence system and blade alignment, lubricate moving parts, and store it in a dry area. Routine maintenance ensures smooth operation and long-lasting performance.