Introduction to Cutting Saws

A cutting saw is one of the most versatile tools every craftsman, DIYer, or professional builder should own. From woodworking and metal fabrication to tile and stone cutting, cutting saws make it easy to achieve clean, accurate, and efficient results. With so many types and models available in 2025, choosing the right cutting saw can feel overwhelming. That’s why this guide covers everything you need to know — from saw types and blade options to safety tips and expert buying advice — so you can find the perfect tool for your next project.

Table of Contents

Types of Cutting Saw

When it comes to choosing the right cutting saw, understanding the different types available is essential. Each saw is designed for specific materials and cutting styles. Whether you’re a professional craftsman or a DIY enthusiast, knowing which saw to use can make your work faster, cleaner, and safer.

1. Hand Saw

A hand saw is the most traditional type of cutting saw, powered by your own effort. It’s perfect for small woodworking tasks and home projects where precision and control are important.

2. Circular Saw

A circular cutting saw uses a round, rotating blade to cut through wood, metal, or plastic. It’s ideal for quick, straight cuts and is a must-have for construction and carpentry projects.

3. Miter Saw

This type of cutting saw is used for making precise angled cuts, often used in furniture making, framing, or molding work. It’s great for achieving accurate joints and clean edges.

4. Table Saw

A table saw is a stationary cutting saw mounted on a workbench. It’s designed for large-scale projects and can cut long, straight lines with ease. It’s commonly used in workshops for building furniture or cabinetry.

5. Jigsaw

A jigsaw is a versatile cutting saw with a thin, up-and-down moving blade that allows you to make curved or custom shapes in wood, metal, or plastic. It’s ideal for craft and DIY work.

6. Reciprocating Saw

Also known as a “sawzall,” this cutting saw features a push-and-pull blade motion, great for demolition or rough cutting. It easily cuts through wood, pipes, and nails.

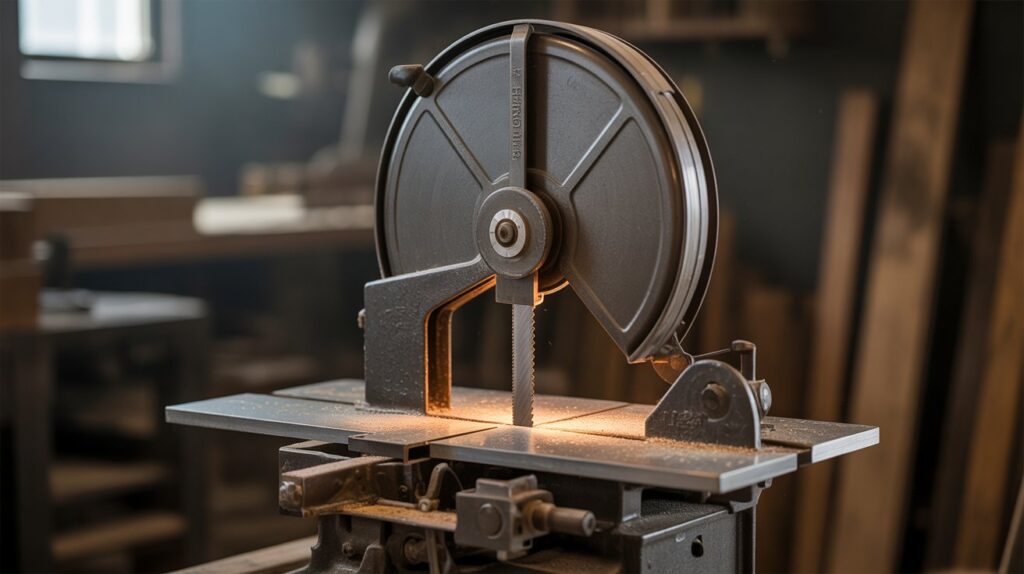

7. Band Saw

A band saw uses a continuous looped blade for cutting wood, metal, or plastic. It’s great for detailed work, curved cuts, and cutting thick materials.

8. Tile and Stone Saw

This cutting saw uses a diamond blade and water cooling system to cut ceramic, marble, or granite without cracking. It’s essential for tile installers and stone workers.

9. Chainsaw

A chainsaw is a heavy-duty cutting saw powered by a chain of sharp teeth that move rapidly around a guide bar. It’s used for cutting trees, logs, and large wooden structures.

10. Hacksaw

A hacksaw is a small frame saw used mainly for cutting metal or plastic pipes. It’s lightweight, affordable, and perfect for plumbing or minor repairs.

Summary Tip

Each cutting saw serves a specific purpose — from precision woodworking to heavy-duty construction. Understanding which type fits your task ensures cleaner results, saves time, and increases safety.

Comparison Table: Types of Cutting Saws

| Type of Cutting Saw | Best For | Material Cut | Power Source | Skill Level |

|---|---|---|---|---|

| Hand Saw | Small woodworking & DIY projects | Wood, plastic | Manual | Beginner |

| Circular Saw | Fast straight cuts | Wood, metal, plastic | Electric / Battery | Intermediate |

| Miter Saw | Angled & precision cuts | Wood, trim, molding | Electric | Intermediate |

| Table Saw | Long, straight, heavy cuts | Wood, plywood | Electric | Advanced |

| Jigsaw | Curved or intricate shapes | Wood, metal, plastic | Electric / Battery | Beginner–Intermediate |

| Reciprocating Saw | Demolition & rough cutting | Wood, pipes, nails | Electric / Battery | Intermediate |

| Band Saw | Smooth curved cuts & thick materials | Wood, metal | Electric | Advanced |

| Tile & Stone Saw | Cutting tiles, marble, granite | Ceramic, stone | Electric (Wet system) | Intermediate |

| Chainsaw | Tree cutting & outdoor work | Wood, logs | Gas / Battery | Intermediate–Advanced |

| Hacksaw | Plumbing & metalwork | Metal, PVC | Manual | Beginner |

“Here’s a quick comparison of the most common types of cutting saws, their best uses, and the materials they work with — to help you choose the right tool for your next project.”

How a Cutting Saw Works

A cutting saw works by using a sharp, toothed blade that moves in a specific motion — either back and forth (reciprocating) or in a continuous circular motion (rotating) — to remove material and create a clean cut. The efficiency of the cut depends on the blade type, speed, and pressure applied.

Basic Working Principle

Every cutting saw operates on a simple principle:

The teeth of the blade grip the material and slice through it as the blade moves. The friction and sharpness of these teeth separate the fibers (in wood) or particles (in metal, tile, etc.), creating a smooth edge.

Manual vs. Power Cutting Saws

- Manual Cutting Saws:

These rely on physical effort. The user pushes and pulls the blade through the material. Examples include hand saws and hacksaws. They provide greater control but require more time and energy. - Power Cutting Saws:

These use electric motors or batteries to rotate or move the blade rapidly. Examples include circular saws, table saws, and jigsaws. They offer high precision and speed, making them ideal for professional or large-scale projects.

Blade Movement and Cutting Action

There are two main types of motion in cutting saws:

- Reciprocating Motion: The blade moves back and forth (used in jigsaws and reciprocating saws).

- Rotary Motion: The blade spins continuously in a circle (used in circular, miter, and table saws).

The motion type determines the kind of cut — smooth, fast, or curved.

Factors That Affect Cutting Performance

The performance of any cutting saw depends on several key factors:

- Blade Material: Diamond, carbide, or steel blades offer different cutting strengths.

- Tooth Design: Fine teeth are best for precision, while coarse teeth are better for rough cuts.

- Speed & Pressure: Too much speed or pressure can cause overheating or uneven cuts.

- Material Type: The density of wood, metal, or tile affects how easily the saw moves through it.

Quick Summary

In short, a cutting saw works by combining the sharpness of its blade, the power of motion, and the control of the user to slice through materials accurately and efficiently. Whether manual or powered, the key lies in choosing the right blade and maintaining proper cutting technique.

Choosing the Right Cutting Saw

Choosing the right cutting saw depends on what material you’re working with, how often you’ll use it, and the level of precision you need. The correct saw not only improves efficiency but also ensures safety and clean, accurate results.

Below are the most important factors to consider when selecting a cutting saw for your project.

Based on Material Type

Different materials require different saws and blades:

- Wood: Circular saws, table saws, and miter saws are ideal for woodwork and carpentry.

- Metal: Use hacksaws, reciprocating saws, or metal-cutting circular saws with carbide-tipped blades.

- Tile & Stone: A wet tile cutting saw with a diamond blade works best for ceramic, marble, or granite.

- Plastic & PVC: Jigsaws or hacksaws make precise, crack-free cuts.

Based on Cutting Style

The type of cut you need determines the saw you should use:

- Straight Cuts: Circular saw or table saw.

- Curved Cuts: Jigsaw or band saw.

- Angled or Miter Cuts: Miter saw.

- Rough Cuts or Demolition: Reciprocating saw.

Based on Frequency of Use

- Occasional / Home Use: A simple hand saw or jigsaw is enough for small DIY projects.

- Frequent / Professional Use: Opt for a durable power cutting saw like a circular, miter, or table saw for consistent performance and speed.

Based on Power Source

Cutting saws are available in two main types:

- Corded (Electric): Provide constant power for heavy-duty cutting jobs.

- Cordless (Battery-powered): Offer portability and flexibility, ideal for outdoor or quick tasks.

Budget and Brand Reliability

Investing in a quality cutting saw pays off in durability, precision, and safety. Well-known brands like DeWalt, Bosch, Makita, and Milwaukee are known for reliable performance and long-lasting tools. Always check reviews and warranties before buying.

Quick Tip

Before purchasing any cutting saw, ask yourself:

- What material will I cut most often?

- Do I need portability or power?

- How much precision does my project require?

The answers will guide you toward the right cutting saw that matches your work needs and budget.

Blade Types and Materials

The blade is the heart of every cutting saw. It determines how clean, fast, and precise your cuts will be. Different blades are designed for specific materials like wood, metal, tile, or stone — and understanding them helps you get the best results while extending the life of your tool.

Carbon Steel Blades

Carbon steel blades are the most common and affordable type used in hand saws and some power saws. They’re flexible and great for cutting soft materials like wood and plastic.

However, they dull quickly when used on harder materials.

High-Speed Steel (HSS) Blades

HSS blades are stronger than carbon steel and retain sharpness for longer periods. These are perfect for metal-cutting saws and applications that involve higher temperatures or friction.

Carbide-Tipped Blades

Carbide-tipped blades are a premium choice for power cutting saws. The carbide edges stay sharp for a long time and easily cut through hardwood, plywood, and even non-ferrous metals.

They’re ideal for professional woodworkers who need precision and durability.

Diamond Blades

Diamond blades are designed for cutting hard, dense materials like ceramic, marble, concrete, and granite. Tiny industrial diamonds embedded in the rim of the blade grind through tough surfaces smoothly and efficiently.

They’re commonly used in tile and stone saws.

Bi-Metal Blades

Bi-metal blades combine flexibility and strength by bonding high-speed steel teeth to a flexible steel body. They are durable and resistant to breaking, making them excellent for reciprocating and band saws used in demolition or metalwork.

Abrasive Blades

These blades don’t have teeth — instead, they use abrasive materials like aluminum oxide or silicon carbide to grind through metal, tile, or concrete. They’re commonly used in cutting saws for heavy-duty construction work.

Quick Tips for Choosing the Right Blade

Replace worn-out or chipped blades immediately for safe and efficient performance.

Always match the blade type with the material you’re cutting.

Use fine-tooth blades for clean cuts and coarse-tooth blades for faster, rougher cuts.

Keep your blades sharp and clean to prevent overheating and rough edges

Replace worn-out or chipped blades immediately for safe and efficient performance.

Safety Tips for Using a Cutting Saw

When working with a cutting saw, safety should always come first. Whether you’re cutting wood, metal, or tiles, saws operate at high speed and can cause serious injuries if not used properly. Following a few essential safety rules ensures both precision and protection during every project.

Always Wear Protective Gear

Before starting any task, make sure you’re wearing safety glasses, gloves, hearing protection, and a dust mask. These protect your eyes from flying debris, your hands from sharp edges, and your lungs from sawdust or metal particles.

Check Your Equipment Before Use

Always inspect your cutting saw before turning it on. Ensure the blade is sharp, securely attached, and free from cracks or damage. Loose or damaged blades can cause accidents or poor cuts.

Use the Right Blade for the Material

Every cutting saw is designed for specific tasks — wood blades, metal blades, and diamond blades each have their purpose. Using the wrong type not only affects performance but also increases the risk of kickback or blade damage.

Maintain a Stable Work Surface

Make sure your material is securely clamped or held in place before cutting. A shaky or unstable surface can cause the saw to slip, leading to uneven cuts or potential injury.

Maintenance and Care

Proper maintenance and care of your cutting saw not only extend its lifespan but also ensure consistent performance and safe operation. Whether you use it for woodworking, metal cutting, or tile work, keeping your saw in top condition is essential for accurate results and user safety.

Clean After Every Use

After every project, take a few minutes to clean your cutting saw. Remove sawdust, metal shavings, or tile dust using a soft brush or compressed air. Avoid letting debris build up around the blade and motor, as it can affect performance and cause overheating.

Check and Sharpen Blades Regularly

A dull blade requires more effort and produces uneven cuts. Regularly inspect and sharpen your saw blade or replace it if needed. For professional results, always use the blade type designed for your material — wood, metal, or stone.

Lubricate Moving Parts

Friction between moving parts can reduce efficiency. Apply a light machine oil or lubricant to the saw’s hinges, bearings, and gears to ensure smooth movement and prevent rust.

Inspect Power Cords and Connections

Before each use, check the power cord for cracks or fraying, and ensure all electrical connections are tight and safe. Damaged cords are one of the most common causes of tool failure and electric shocks.

Store Properly

When not in use, store your cutting saw in a dry, dust-free environment. Use a protective case or cover to prevent moisture or rust from damaging the blade and motor.

Replace Worn Parts Promptly

If you notice reduced power, strange noises, or wobbling during operation, inspect the internal parts. Replace worn-out brushes, switches, or bearings immediately to keep the saw functioning safely and efficiently.

Schedule Professional Servicing

For heavy or frequent use, consider having your cutting saw serviced by a professional once or twice a year. Regular servicing ensures internal parts remain in perfect working order

Pro Tip:

Keep a small maintenance log to track blade changes, oiling, and part replacements. This helps you plan regular care and keeps your cutting saw in peak condition.

In summary, regular maintenance and care prevent costly repairs and ensure your cutting saw always performs at its best. A clean, sharp, and well-maintained saw is not only more efficient but also safer and more enjoyable to use.

Top 5 Cutting Saws in 2025 (Buyer’s Guide)

Finding the best cutting saw in 2025 can be challenging with so many brands and models available. Whether you’re a DIY enthusiast or a professional contractor, the right tool can make a huge difference in performance, safety, and precision. Below is a list of the top 5 cutting saws that stand out for their quality, durability, and value for money.

DEWALT DWE575SB 7-1/4” Lightweight Circular Saw

Best for: Woodworking & framing

Why it’s great: The DEWALT DWE575SB is one of the most popular cutting saws for its powerful 15-amp motor and lightweight design. It delivers clean, precise cuts and includes an electric brake for added safety.

Pros: Durable, compact, easy to handle

Cons: Slightly loud during operation

Bosch GCM12SD 12” Dual-Bevel Miter Saw

Best for: Precision cuts and angled joints

Why it’s great: Known for its axial-glide system, the Bosch GCM12SD provides smooth, accurate motion and saves workspace. Ideal for trim work, furniture building, and woodworking projects.

Pros: Excellent precision, smooth glide arm

Cons: Heavy and less portable

Makita XSR01PT 18V Cordless Rear Handle Circular Saw

Best for: Professionals needing mobility

Why it’s great: This cordless cutting saw offers high torque and runtime with its brushless motor and dual 18V batteries. It’s perfect for users who need power without the hassle of cords.

Pros: Cordless freedom, great battery life

Cons: Expensive batteries

Milwaukee M18 FUEL Sawzall Reciprocating Saw

Best for: Demolition and rough cutting

Why it’s great: The Milwaukee Sawzall is an iconic cutting saw known for its durability and raw power. It can cut through wood, metal, and even nails with ease. Great for plumbing, construction, and renovation work.

Pros: Versatile, long battery life

Cons: Not ideal for precision cuts

SKIL 3550-02 7-Inch Wet Tile Saw

Best for: Tile and stone cutting

Why it’s great: If your projects involve tiles, marble, or granite, this SKIL wet cutting saw is an excellent choice. It includes a water cooling system to reduce dust and overheating.

Pros: Precise, clean cuts on tiles

Cons: Not suitable for wood or metal

Comparison Summary Table

| Model | Best For | Power Type | Key Feature | User Level |

|---|---|---|---|---|

| DEWALT DWE575SB | Woodworking | Electric | Lightweight design | Beginner–Pro |

| Bosch GCM12SD | Precision cuts | Electric | Axial-glide system | Professional |

| Makita XSR01PT | Mobility | Battery | Cordless with high torque | Intermediate–Pro |

| Milwaukee M18 Sawzall | Demolition | Battery | Heavy-duty cutting | Intermediate |

| SKIL 3550-02 | Tile & stone work | Electric | Wet cooling system | Beginner–Intermediate |

Pro Tip:

When choosing a cutting saw, consider your project type, material, and skill level. For example, woodworkers may prefer circular or miter saws, while tile and plumbing professionals might benefit more from wet tile or reciprocating saws.

Common Mistakes to Avoid When Using Cutting Saws

Even the best cutting saw can perform poorly—or even become dangerous—if it’s used the wrong way. Many beginners and even experienced users make simple mistakes that reduce efficiency, damage the tool, or risk injury. Here are the most common mistakes to avoid when using cutting saws and how to use them safely and effectively.

Using the Wrong Saw for the Job

One of the biggest mistakes is using a cutting saw designed for one material on another. For example, a wood saw shouldn’t be used to cut metal or tiles. Always choose the right type of saw and blade for your specific material to avoid dulling the blade or causing kickback.

Ignoring Safety Gear

Skipping safety gear is a major hazard. Always wear safety glasses, gloves, and ear protection when operating a cutting saw. Even small cuts produce dust and flying debris that can cause injury.

Not Checking the Blade Condition

A dull or damaged blade not only slows your work but also increases the chance of slipping or overheating. Always inspect the blade before each use and replace it if you notice chips, rust, or bending.

Cutting Too Fast or Applying Too Much Force

A cutting saw works best when you let the blade do the work. Forcing the saw through the material can overheat the motor, dull the blade, and lead to uneven cuts. Maintain steady pressure and smooth movement for cleaner results.

Forgetting to Secure the Material

Always clamp or hold your material firmly before cutting. Loose boards or tiles can shift unexpectedly, causing crooked cuts or dangerous kickbacks. A stable surface ensures accuracy and safety.

Poor Maintenance and Cleaning

Failing to clean and maintain your cutting saw leads to debris buildup, rust, and performance loss. Regular cleaning, lubrication, and blade sharpening will extend the life of your saw and keep it cutting smoothly.

Ignoring the User Manual

Each model of cutting saw has unique features and safety recommendations. Skipping the manual means you may miss out on essential setup instructions, blade compatibility info, or maintenance tips.

Not Using the Correct Cutting Technique

For beginners, poor body positioning or incorrect cutting angles can lead to uneven cuts and tool fatigue. Keep a balanced stance, align the saw properly, and always cut away from your body.

Pro Tip:

If you’re unsure how to operate a new cutting saw, practice on scrap material first. This helps you understand the tool’s speed, weight, and behavior before starting your actual project.

In summary, avoiding these common mistakes will make your work with any cutting saw smoother, safer, and more professional. A little preparation and care can prevent accidents, improve precision, and extend the life of your tools.

1. What is the best cutting saw for wood?

The best cutting saw for wood depends on your project type. For straight cuts, a circular saw is ideal due to its speed and precision. For angled or detailed cuts, a miter saw works best. If you need portability, a cordless circular saw offers great power with flexibility for DIY and job-site work.

2. Can one cutting saw cut different materials?

Yes, but only with the right blade. A single cutting saw can handle wood, metal, plastic, or tile if fitted with a blade designed for that material. For example, a circular saw with a carbide-tipped blade works for wood, while a diamond blade can cut tiles or stone safely.

3. How often should I change saw blades?

You should replace your cutting saw blade whenever you notice slower cutting, burning marks, or rough edges. For those who use their saws regularly, it’s best to replace the blade every couple of months to maintain sharpness and smooth performance. Occasional users can go longer, but regular inspections are key — a sharp blade ensures clean, efficient cuts and prevents tool strain.

4. What’s the difference between a miter saw and a circular saw?

A miter saw is designed for precision angle and crosscuts — perfect for trim work, framing, and furniture projects. A circular saw, on the other hand, is more versatile and portable, ideal for straight, long cuts through wood or other materials. Both are essential tools for woodworking and construction.

5. Are cordless saws as powerful as electric ones?

Modern cordless cutting saws have advanced battery technology that makes them almost as powerful as corded versions. While corded saws still offer continuous power for heavy-duty tasks, cordless models provide excellent mobility, convenience, and performance — ideal for on-site and outdoor projects.

Conclusion

Choosing the right cutting saw can completely transform the quality and efficiency of your work. Whether you’re handling wood, metal, tiles, or stone, there’s a saw built perfectly for your needs. From lightweight hand saws to powerful electric models, the right tool not only saves time but also ensures precision and safety in every cut.

By understanding the types of cutting saws, learning how they work, and avoiding common mistakes, you’ll be better equipped to make the right choice for any project. Remember — maintaining your cutting saw through regular cleaning, sharpening, and safe operation keeps it performing like new for years.

If you’re ready to upgrade your toolkit, explore our expert reviews and buying guides on CutterZone.com to find the perfect cutting saw for your next project.

Because here, every cut matters.