Introduction

A hand saw blade is one of the most essential tools for woodworking and DIY projects. Selecting the right blade can significantly impact cutting efficiency, accuracy, and overall project quality. In this guide, we will explore the different types of hand saw blades, materials, tooth designs, and key factors to consider, helping you make an informed choice for every cutting task.

Table of Contents

Types of Hand Saw Blades

Choosing the right hand saw blade depends largely on the type of cutting work you plan to do. Different blade designs are created for specific cutting tasks, and using the correct one improves accuracy, speed, and overall results. Below are the most common types of hand saw blades and their uses.

Rip Cut Hand Saw Blade

A rip cut hand saw blade is designed to cut along the wood grain. Its teeth are shaped like small chisels, allowing it to remove material quickly. This type of hand saw blade is ideal for rough cutting and tasks where speed is more important than a smooth finish.

Crosscut Hand Saw Blade

A crosscut hand saw blade is made for cutting across the wood grain. The teeth are angled and sharpened to slice cleanly through fibers, producing a smoother cut. This type is commonly used for finish work, furniture making, and general woodworking projects.

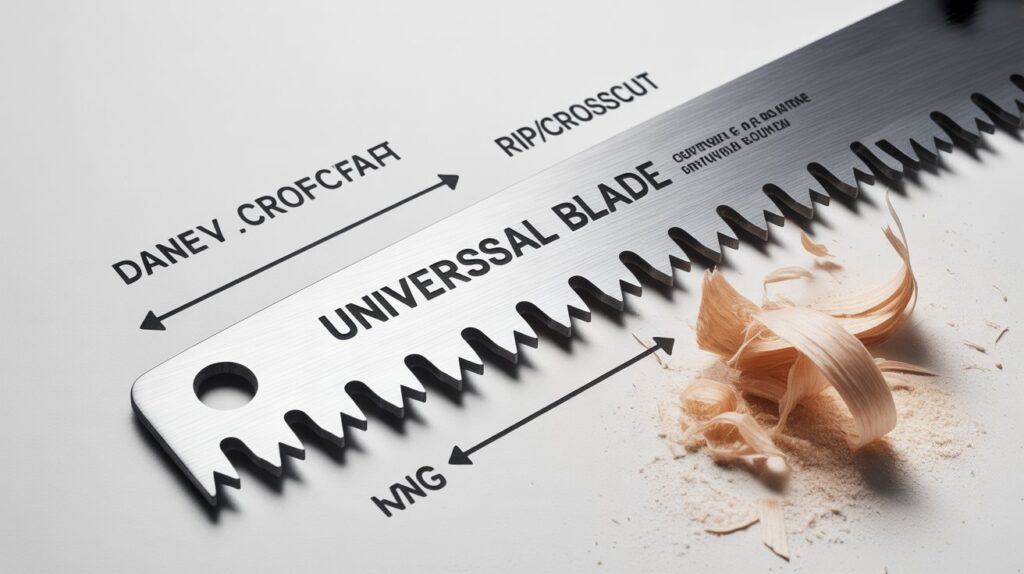

Universal Hand Saw Blade

A universal hand saw blade combines features of both rip and crosscut designs. It offers balanced performance for cutting in multiple directions, making it a practical choice for DIY users who need one blade for various tasks.

Fine-Tooth Hand Saw Blade

Fine-tooth hand saw blades have a higher teeth-per-inch (TPI) count, which allows for clean and precise cuts. They are well suited for detailed work, trim cutting, and thinner materials where accuracy is critical.

Coarse-Tooth Hand Saw Blade

A coarse-tooth hand saw blade has fewer teeth per inch, allowing for faster cutting. These blades are best for rough cuts, thick wood, and construction tasks where speed matters more than finish quality.

Specialty Hand Saw Blades

Some hand saw blades are designed for specific materials such as plastic, laminate, or soft metal. These specialty blades feature unique tooth patterns and hardened steel construction to handle tougher materials without excessive wear.

Understanding the different types of hand saw blades helps you select the best option for your project, ensuring efficient cutting and professional-quality results.

Back Saw Blade

A back saw blade features a reinforced spine along the top edge, which adds stiffness and improves cutting accuracy. This type of hand saw blade is commonly used for precision woodworking, such as making joints, dovetails, and tenons. The rigid back helps maintain straight cuts with minimal effort.

Panel Saw Blade

A panel saw blade is a general-purpose hand saw blade designed for cutting large wooden panels and boards. It typically has a longer blade length and medium tooth spacing, allowing for smooth and controlled cuts. This blade is ideal for carpentry, framing, and everyday woodworking tasks.

Flush Cut Hand Saw Blade

A flush cut hand saw blade is designed to cut material flush with a surface without damaging it. The blade has little to no tooth set, preventing scratches on nearby surfaces. This type of hand saw blade is often used for trimming dowels, plugs, and excess wood in finished projects.

Japanese-Style Hand Saw Blade

Japanese-style hand saw blades cut on the pull stroke rather than the push stroke. This design allows for thinner blades, greater control, and cleaner cuts. These hand saw blades are highly regarded for precision work and require less force, making them efficient and easy to use.

Material Used in Hand Saw Blades

The material of a hand saw blade plays a critical role in cutting performance, durability, and long-term reliability. High-quality materials ensure cleaner cuts, better edge retention, and reduced wear during repeated use. Understanding the most common materials used in hand saw blades helps you choose the right option for your woodworking needs.

Carbon Steel Hand Saw Blade

Carbon steel is one of the most widely used materials in hand saw blades. A carbon steel hand saw blade offers excellent sharpness and is easy to resharpen, making it a popular choice for woodworking hand saws. These blades provide good cutting performance but require proper maintenance, as they can be prone to rust if not stored correctly.

Hardened Steel Hand Saw Blade

A hardened steel hand saw blade is treated to increase strength and edge durability. This process allows the blade to stay sharp longer, reducing the need for frequent sharpening. Hardened steel blades are commonly used in manual cutting tools designed for consistent and precise cutting, especially in professional woodworking environments.

Alloy Steel Hand Saw Blade

Alloy steel hand saw blades are manufactured by combining steel with other elements to improve toughness and resistance to wear. These blades offer a balance between flexibility and strength, making them suitable for demanding cutting tasks. An alloy steel hand saw blade performs well when cutting hardwood and other dense materials.

High-Carbon Hardened Steel

High-carbon hardened steel is used in premium hand saw blades designed for durability and precision. This material allows for a fine cut saw blade with excellent tooth retention. It is often found in rip cut saw blade and crosscut saw blade designs where accuracy and clean edges are essential.

Coated Hand Saw Blades

Some hand saw blades feature protective coatings such as anti-rust or low-friction finishes. These coatings help reduce corrosion, improve cutting speed, and extend blade lifespan. Coated steel saw blades also require less maintenance and perform consistently in various working conditions.

Material Impact on Performance

The choice of material directly affects saw blade tooth design, cutting efficiency, and maintenance needs. A well-made hand saw blade material ensures smoother cuts, longer service life, and better control, making it an essential factor when selecting a precision cutting tool.

Choosing the right material for a hand saw blade ensures reliable performance, minimal maintenance, and long-lasting value for both DIY users and professional woodworkers.

Tooth Design and Teeth Per Inch (TPI)

The tooth design of a hand saw blade directly affects how efficiently it cuts and the quality of the finished surface. Along with tooth shape, teeth per inch (TPI) is a key factor that determines cutting speed, smoothness, and control. Understanding both elements helps in selecting the best hand saw blade for specific woodworking tasks.

Hand Saw Blade Tooth Design

Tooth design refers to the shape, angle, and set of the teeth on a hand saw blade. Rip cut saw blade teeth are shaped like small chisels, allowing fast cutting along the wood grain. Crosscut saw blade teeth are angled and sharpened to slice across fibers, producing cleaner and smoother results. Some hand saw blade types feature a hybrid tooth design, offering balanced performance for both cutting directions.

The saw blade tooth design also affects how much material is removed during each stroke. Proper tooth set creates enough clearance to prevent binding while maintaining cutting accuracy, which is essential for precision cutting tools.

Understanding Teeth Per Inch (TPI)

Teeth per inch (TPI) refers to the number of teeth present in one inch of the hand saw blade. A lower TPI means fewer, larger teeth that remove material quickly, making it suitable for rough cuts and faster cutting performance. A higher TPI produces finer cuts with smoother edges, ideal for detailed woodworking and finish work.

Choosing the Right TPI for Your Project

Selecting the correct hand saw blade TPI depends on the material and desired finish. Coarse blades with low TPI are commonly used for thick wood and construction tasks. Fine cut saw blades with higher TPI are better for thin materials, trim work, and projects requiring clean edges.

Impact on Performance and Control

The combination of tooth design and TPI determines how a hand saw blade performs during use. A well-matched blade provides smoother cuts, better control, and reduced effort. Choosing the right balance improves accuracy and overall efficiency when working with woodworking hand saws.

Understanding tooth design and TPI ensures better results and helps extend the lifespan of your hand saw blade by reducing unnecessary strain and wear.

Blade Length and Thickness

The length and thickness of a hand saw blade have a direct impact on cutting control, efficiency, and overall performance. Choosing the correct blade dimensions ensures better accuracy and reduces effort during manual cutting tasks.

Hand Saw Blade Length

Hand saw blade length determines how much material can be cut in a single stroke. Longer blades allow for wider and more efficient strokes, making them suitable for cutting large boards and panels. A longer hand saw blade is commonly used in carpentry and general woodworking where speed and reach are important.

Shorter hand saw blades provide greater control and are ideal for detailed work and tight spaces. These blades are often preferred for precision cutting tasks where accuracy matters more than cutting speed. Selecting the right hand saw blade length depends on the size of the material and the level of control required.

Hand Saw Blade Thickness

Blade thickness affects rigidity and stability during cutting. A thicker hand saw blade offers more stiffness, helping maintain straight cuts and reducing blade flex. This makes thicker blades a reliable choice for woodworking hand saws used in demanding applications.

Thinner hand saw blades cut with less resistance and require less effort, which improves cutting performance in lighter materials. However, thinner blades may bend if excessive pressure is applied, making them better suited for fine cut saw blade applications and controlled precision cutting tools.

Balance Between Length and Thickness

The ideal hand saw blade balances length and thickness to match the intended task. Longer and thicker blades provide strength and durability, while shorter and thinner blades offer improved maneuverability and accuracy. Understanding this balance helps in selecting the best hand saw blade for both efficiency and clean results.

Choosing the proper blade length and thickness ensures smoother cuts, better control, and long-term reliability when working with manual cutting tools.

Cutting Performance and Accuracy

The cutting performance of a hand saw blade determines how efficiently it removes material and how clean the final cut appears. Accuracy is equally important, especially in woodworking projects where precision affects the quality of joints and overall finish. A well-designed hand saw blade improves both speed and control during manual cutting.

Factors Affecting Cutting Performance

Several elements influence how a hand saw blade performs, including blade material, tooth design, and teeth per inch (TPI). A properly matched hand saw blade for wood allows smoother strokes and reduces resistance, resulting in consistent cutting performance. Blades with optimized saw blade tooth design cut efficiently without excessive force, making them easier to handle for both professionals and DIY users.

Accuracy in Manual Cutting Tools

Accuracy depends on blade stability and sharpness. A durable hand saw blade with proper thickness and rigidity helps maintain straight cuts, reducing the chances of wandering or uneven edges. Fine cut saw blades are especially effective for tasks that require clean lines and precise measurements, such as trim work and furniture building.

Control and Precision

Good cutting accuracy comes from a combination of balanced blade length and ergonomic handling. A well-constructed hand saw blade provides better control, allowing users to follow marked lines closely. Precision cutting tools rely on sharp, evenly set teeth to deliver smooth and accurate results across different materials.

Performance Across Materials

The best hand saw blade performs consistently on various materials without tearing or splintering. Whether cutting softwood or hardwood, a quality blade maintains steady cutting performance while preserving surface quality. This reliability makes a well-designed hand saw blade an essential part of any woodworking tools guide.

Understanding cutting performance and accuracy helps in selecting a hand saw blade that delivers clean results, efficient cutting, and dependable precision in every project.

Handle Compatibility and Ergonomics

The handle of a hand saw blade plays a significant role in cutting efficiency, comfort, and overall safety. Proper handle design ensures that users can maintain control during prolonged use while reducing fatigue and improving accuracy. Understanding handle compatibility and ergonomics is essential when selecting a woodworking hand saw.

Ergonomic Handle Design

An ergonomic hand saw blade handle is shaped to fit comfortably in the hand, allowing for a secure grip and natural wrist alignment. Handles made from materials such as rubber, plastic, or wood can provide cushioning and reduce vibration during cutting. This design minimizes strain on the hand and wrist, making the hand saw blade easier to use for extended periods.

Handle Compatibility with Blade Type

Different hand saw blades may require specific handle designs to maximize control. For example, a back saw blade often has a rigid handle to maintain precision in fine cuts, while a rip cut saw blade may feature a larger, angled handle for more leverage and force. Choosing a handle that complements the blade type improves cutting performance and control.

Impact on Cutting Accuracy

A comfortable and compatible handle allows the user to guide the hand saw blade steadily along the cutting line. This improves accuracy, especially when performing detailed work or precise joinery. Handles that fit poorly can lead to uneven cuts, decreased performance, and increased effort.

Material and Grip Considerations

The material and texture of the handle affect grip stability. Non-slip surfaces on a hand saw blade handle enhance safety and control, even in damp or slippery conditions. High-quality handles combined with durable hand saw blades make manual cutting tools more reliable and efficient.

Choosing a hand saw blade with an ergonomic and compatible handle ensures better control, less fatigue, and improved cutting precision, making it a key factor for both DIY users and professional woodworkers.

Durability and Maintenance

The durability of a hand saw blade is a key factor in its long-term performance and value. A durable blade maintains sharpness, resists wear, and performs consistently over time. Proper maintenance further extends the life of the blade, ensuring efficient and precise cutting for every woodworking project.

Factors Affecting Durability

The material and construction of a hand saw blade determine its durability. High-carbon steel and hardened alloy steel blades resist bending, chipping, and dulling, even during repeated use. Tooth design and thickness also impact longevity, as blades with properly set teeth experience less stress and wear. A well-made hand saw blade provides consistent cutting performance across different materials without frequent replacement.

Maintenance Practices

Maintaining a hand saw blade involves regular cleaning, sharpening, and proper storage. After each use, removing sawdust, resin, and moisture prevents rust and corrosion. Fine cut saw blades and high-quality hand saw blades may require occasional sharpening to maintain optimal cutting efficiency. Using a sharpening file or professional service ensures the teeth remain precise and effective.

Preventing Rust and Corrosion

Coating the hand saw blade with a light layer of oil or using corrosion-resistant blades helps protect against rust. Proper storage in a dry environment further preserves blade integrity, preventing damage that can reduce cutting accuracy and efficiency.

Impact on Performance and Safety

A well-maintained hand saw blade not only lasts longer but also delivers smoother, more accurate cuts. Regular maintenance reduces the effort required during cutting and minimizes the risk of blade binding or breaking, making manual cutting tools safer and more reliable.

Prioritizing durability and maintenance ensures that your hand saw blade remains a dependable tool, providing consistent performance, precision, and long-term value for woodworking and DIY projects.

Choosing the Right Hand Saw Blade for Your Project

Selecting the right hand saw blade is essential for achieving efficient, accurate, and clean cuts in any woodworking or DIY project. The choice of blade affects cutting performance, precision, and ease of use, making it important to consider several key factors before making a purchase.

Consider the Material Being Cut

The type of material determines which hand saw blade will perform best. Coarse blades with fewer teeth per inch (TPI) are ideal for thick wood and softwood, allowing faster material removal. Fine cut saw blades with higher TPI are better for hardwood, plywood, or detailed trim work, providing cleaner edges and smoother finishes. Specialty blades may be required for cutting plastic, laminate, or soft metals.

Match Blade Type to the Cutting Task

Different hand saw blade types are designed for specific cutting directions and applications. Rip cut saw blades work along the grain of the wood, crosscut blades are designed for cutting across the grain, and universal blades offer versatility for multiple tasks. Selecting the appropriate blade type ensures efficiency and reduces strain during manual cutting.

Evaluate Blade Length and Thickness

Longer blades allow for longer strokes and faster cutting of large boards, while shorter blades provide better control in detailed or tight-space work. Blade thickness affects rigidity; thicker blades maintain straight cuts, while thinner blades offer more maneuverability for precise cuts. Choosing the right combination supports both speed and accuracy.

Check Handle Compatibility and Comfort

An ergonomic handle enhances control and reduces fatigue. Ensure the handle complements the chosen hand saw blade type and allows a secure grip during cutting. Proper handle design is especially important for extended projects or precision work.

Factor in Durability and Maintenance

High-quality materials such as carbon steel, hardened steel, or alloy steel increase the lifespan of a hand saw blade. Regular maintenance, including cleaning, sharpening, and rust prevention, preserves performance and ensures safety during use.

By considering material, blade type, length, thickness, handle design, and durability, you can choose the right hand saw blade for your project. This ensures efficient cutting, precise results, and a reliable tool that meets both professional and DIY woodworking needs.

Price, Value, and Buying Tips

When selecting a hand saw blade, understanding price, value, and key buying considerations is essential to make a cost-effective and practical choice. A higher price does not always guarantee the best performance, so evaluating quality, durability, and suitability for your tasks is important.

Price vs. Quality

Hand saw blades are available at a wide range of prices. Budget-friendly options may be sufficient for occasional DIY use, but professional woodworking often requires high-carbon or hardened steel blades that offer better cutting performance and longevity. Investing in a quality hand saw blade can save money over time by reducing the need for frequent replacements and maintenance.

Evaluating Value

Value is determined by the combination of performance, durability, and versatility. A hand saw blade that cuts efficiently, maintains sharpness, and works across multiple materials provides greater value than a cheaper, less durable alternative. Consider blades with corrosion-resistant coatings or ergonomic handles, as these features enhance usability and lifespan.

Buying Tips

- Identify Your Needs: Choose a hand saw blade based on the type of material and cutting tasks you will perform.

- Check Blade Specifications: Look for details like TPI, blade length, thickness, and material to ensure suitability for your projects.

- Read Reviews and Brand Reputation: Reliable brands often produce hand saw blades with consistent quality and performance.

- Consider Maintenance Requirements: Select blades that are easy to clean, sharpen, and store to maximize longevity.

- Balance Price and Performance: Avoid the cheapest options if long-term use and precision are important, but also don’t overspend on features you won’t use.

By evaluating price, performance, and features, you can select a hand saw blade that offers the best value for your woodworking or DIY projects, ensuring efficient cutting, durability, and precise results.

Conclusion

Choosing the right hand saw blade is crucial for achieving accurate, efficient, and clean cuts in any woodworking or DIY project. By considering factors such as blade type, material, tooth design, TPI, length, thickness, handle ergonomics, and durability, you can select a blade that meets your specific needs. Proper maintenance and thoughtful selection ensure long-term performance, better cutting precision, and reliable results. Investing time in choosing the best hand saw blade will make your woodworking tasks easier, safer, and more professional.

FAQs About Hand Saw Blade

Q.1. What is the use of a hand saw?

A hand saw is used for cutting wood, plastic, or soft materials manually. It helps in shaping, trimming, and making precise cuts in woodworking, carpentry, and DIY projects

Q.2. Is a hacksaw a hand saw?

Yes, a hacksaw is a type of hand saw specifically designed for cutting metal or plastic. Unlike traditional wood saws, it has a fine-toothed blade and a frame for tensioning.

Q.3. What is the most useful DIY saw?

The most useful DIY saw is a crosscut hand saw or universal hand saw blade because it can handle a variety of tasks like cutting wood panels, trimming boards, and general household projects.

Q.4. Best hand saw blades for wood?

The best hand saw blades for wood are made of high-carbon steel or hardened alloy steel with the right TPI for your cutting type—coarse for rough cuts and fine for precise finish cuts. Rip cut, crosscut, and universal blades are ideal.

Q.5. Mini hand saw for wood?

A mini hand saw is a compact, lightweight saw designed for small woodworking tasks, detailed cuts, or working in tight spaces. It’s ideal for craft projects, model making, and DIY home repairs.