Introduction

Table saw components are the building blocks of every successful woodworking project. Knowing the function of each part, from the blade and rip fence to safety features like the riving knife and push stick, helps woodworkers achieve precise cuts, improve workshop safety, and maintain the saw for long-term performance. This guide covers all major and essential components of a table saw, explaining their purpose, use, and importance in clear and practical terms.

Table of Contents

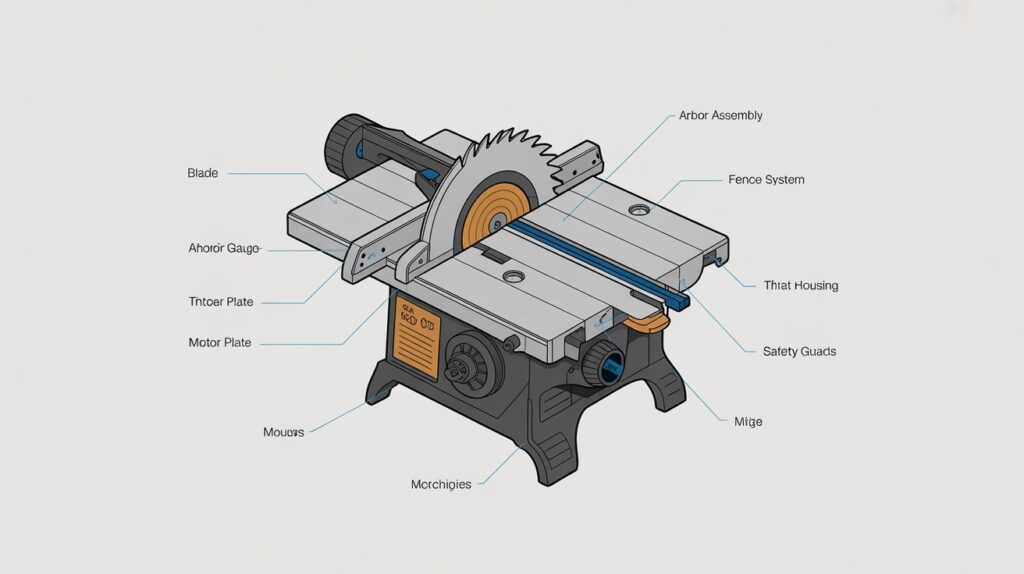

What Are Table Saw Components?

Table saw components are the individual mechanical, structural, and safety parts that work together to perform cutting operations. These components control blade movement, guide materials, provide power, and protect the user. Knowing how these parts function helps users operate the saw correctly, maintain it properly, and avoid accidents.

Why Understanding Table Saw Components Matters for Buyers

Understanding table saw components is essential for making a confident and informed buying decision. Each component directly affects how the saw performs, how safe it is to use, and how long it will last.

When buyers understand the role of key table saw components, they benefit in several important ways:

Improved cutting accuracy:

High-quality components such as a stable tabletop, precision rip fence, and well-aligned blade system ensure cleaner, more accurate cuts, which is especially important for professional and repeatable work.

Enhanced operator safety:

Modern safety components like riving knives, blade guards, and anti-kickback systems significantly reduce the risk of accidents. Buyers who recognize these features can choose safer, more reliable models.

Longer tool lifespan:

Durable motors, solid arbor assemblies, and effective dust collection systems reduce wear and tear. Knowing these components helps buyers invest in saws built for long-term performance rather than short-term use.

Easier maintenance and lower ownership costs:

Understanding how components function makes it easier to identify worn parts, perform routine maintenance, and avoid costly repairs or replacements.

Final Note Understanding all table saw components helps improve cutting accuracy, safety, and maintenance. Whether you are a beginner or a professional woodworker, knowing how each component works ensures better performance and longer tool life.

Main Table Saw Components and Their Functions

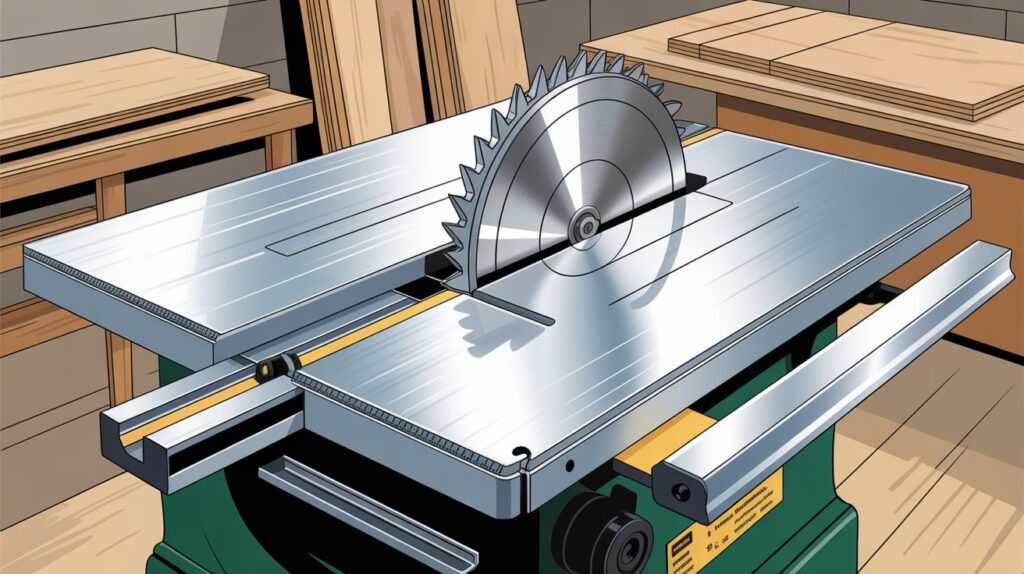

1. Tabletop (Work Surface)

The tabletop (work surface) is one of the most important table saw components because it directly affects cutting accuracy, stability, and overall performance. This flat surface supports the material during cutting and is typically made from cast iron or aluminum to reduce vibration and improve cutting precision. A well-machined tabletop helps keep saw blade alignment and calibration accurate, which is essential for clean and consistent results when using wood cutting equipment. The tabletop also integrates miter gauge components, rip fence for table saw systems, and table saw accessories, allowing smooth material guidance and controlled movement. As a core part of modern woodworking tools, a properly maintained tabletop enhances workshop safety, supports effective kickback prevention, and ensures reliable performance when working with different table saw parts and circular saw components.

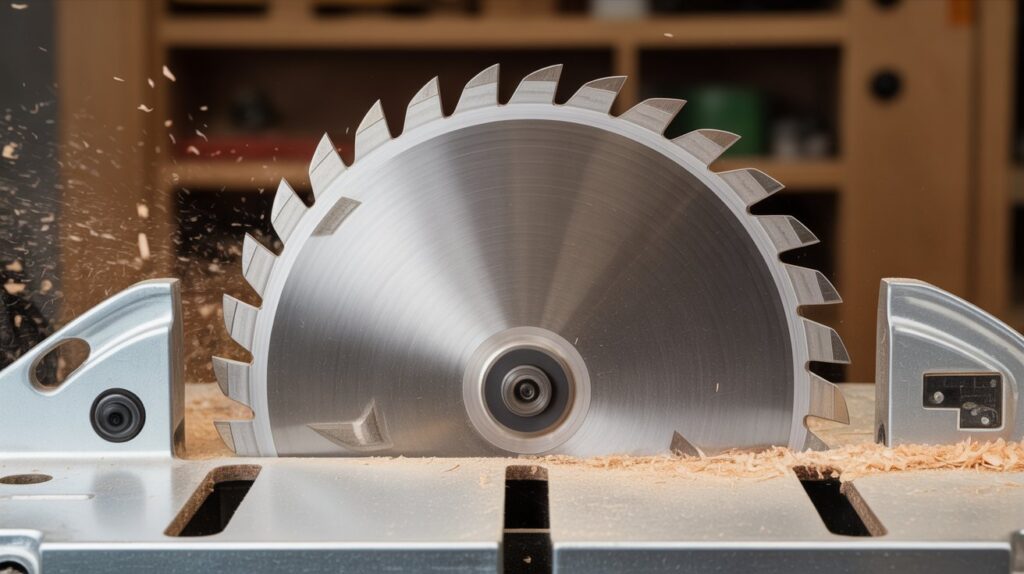

2. Saw Blade

The saw blade is the primary cutting element among all table saw components, directly responsible for cut quality, speed, and accuracy. Different table saw blade types are designed for specific tasks, such as ripping, crosscutting, or combination cutting, and choosing the right blade improves cutting precision while reducing material damage. As one of the most critical table saw parts, the blade must be properly installed on the table saw motor and arbor to maintain correct saw blade adjustment and balance. High-quality blades also support better kickback prevention and smoother operation across various wood cutting equipment setups. When paired with proper table saw safety components and compatible circular saw components, the saw blade ensures clean, controlled cuts and reliable performance in professional and home woodworking tools alike.

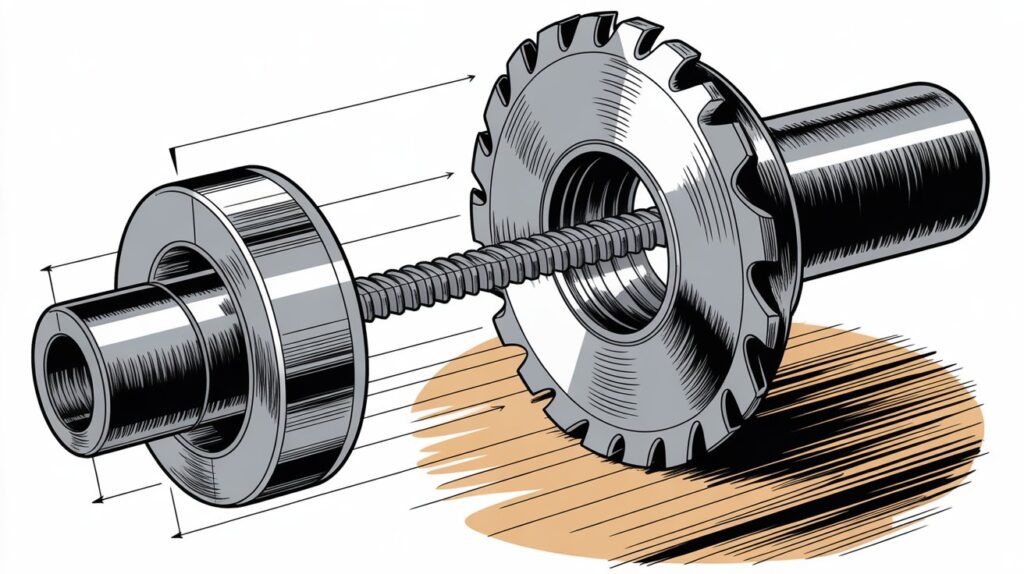

3. Arbor

The arbor is a critical mechanical element among table saw components, as it is the shaft that holds and rotates the saw blade during operation. As part of the table saw motor and arbor system, it transfers power directly from the motor to the blade, making proper blade alignment and calibration essential for smooth and accurate cutting. A well-aligned arbor minimizes vibration, improves cutting precision, and supports effective kickback prevention, which is vital for workshop safety. Since the arbor directly impacts blade stability, it is one of the most important table saw parts to inspect during routine table saw maintenance parts checks to ensure consistent performance in woodworking tools and wood cutting equipment.

4. Arbor Nut and Washer

The arbor nut and washer are small but essential table saw components that secure the saw blade firmly to the arbor during operation. These table saw parts ensure the blade remains stable at high speeds, which directly affects cutting precision and reduces vibration. Properly tightened arbor hardware supports accurate blade alignment and calibration and plays an important role in kickback prevention, improving overall workshop safety. As part of routine table saw maintenance parts, checking the arbor nut and washer helps maintain reliable performance across all wood cutting equipment and professional woodworking tools.

5. Throat Plate (Insert Plate)

The throat plate (insert plate) is an important support element among table saw components, positioned around the blade opening on the tabletop. This component helps stabilize the workpiece close to the blade, improving cutting precision and reducing tear-out during cuts. As one of the functional table saw parts, a well-fitted throat plate supports proper saw blade adjustment and accurate blade alignment and calibration. Using quality or zero-clearance insert plates also enhances kickback prevention and overall workshop safety, making them valuable table saw accessories for efficient wood cutting equipment and everyday woodworking tools.

6. Rip Fence

The rip fence is one of the most important guiding systems among table saw components, designed to keep the workpiece aligned parallel to the blade for straight and accurate cuts. A properly adjusted rip fence for table saw improves cutting precision by ensuring consistent spacing between the blade and material. As a key part of essential table saw parts, the rip fence works closely with miter gauge components and other table saw accessories to support controlled cutting and reliable kickback prevention. A stable, square fence also enhances workshop safety and overall efficiency when using professional woodworking tools and wood cutting equipment.

7. Fence Rails

Fence rails are essential alignment and support elements among table saw components, allowing the rip fence to slide smoothly and lock securely at precise measurements. These rails directly affect the accuracy of rip fence for table saw systems, helping maintain consistent spacing for improved cutting precision. As durable table saw parts, fence rails contribute to proper blade alignment and calibration by keeping cuts straight and repeatable. Well-built rails also enhance workshop safety and efficiency, making them a vital part of professional woodworking tools and reliable wood cutting equipment.

8. Miter Gauge

The miter gauge is a precision-guiding tool among table saw components that allows accurate crosscuts and angled cuts by guiding the workpiece through the miter slot. As one of the essential miter gauge components, it supports controlled movement and improved cutting precision, especially for angled woodworking tasks. The miter gauge works alongside table saw accessories to enhance saw blade adjustment and maintain proper blade alignment and calibration. When used correctly, it also contributes to kickback prevention and better workshop safety, making it a valuable feature of professional woodworking tools and efficient wood cutting equipment.

9. Miter Slots

Miter slots are precisely machined grooves on the tabletop that are essential table saw components for guiding the miter gauge components and other jigs. They ensure accurate and stable movement of the workpiece, improving cutting precision and supporting proper blade alignment and calibration. As key table saw parts, miter slots work with table saw accessories to enhance safety, enable repeatable cuts, and assist in kickback prevention, making them vital for safe and efficient use of woodworking tools and wood cutting equipment.

Power and Adjustment Components

10. Motor

The motor is a critical power source among table saw components, driving the blade to perform efficient and precise cuts. As part of the table saw motor and arbor system, it provides the torque needed for different table saw parts and supports consistent cutting precision across various materials. A well-maintained motor ensures proper saw blade adjustment and reliable blade alignment and calibration, while also enhancing kickback prevention and overall workshop safety. Strong, efficient motors are essential for professional woodworking tools and durable wood cutting equipment, making them a key factor in saw performance and longevity.

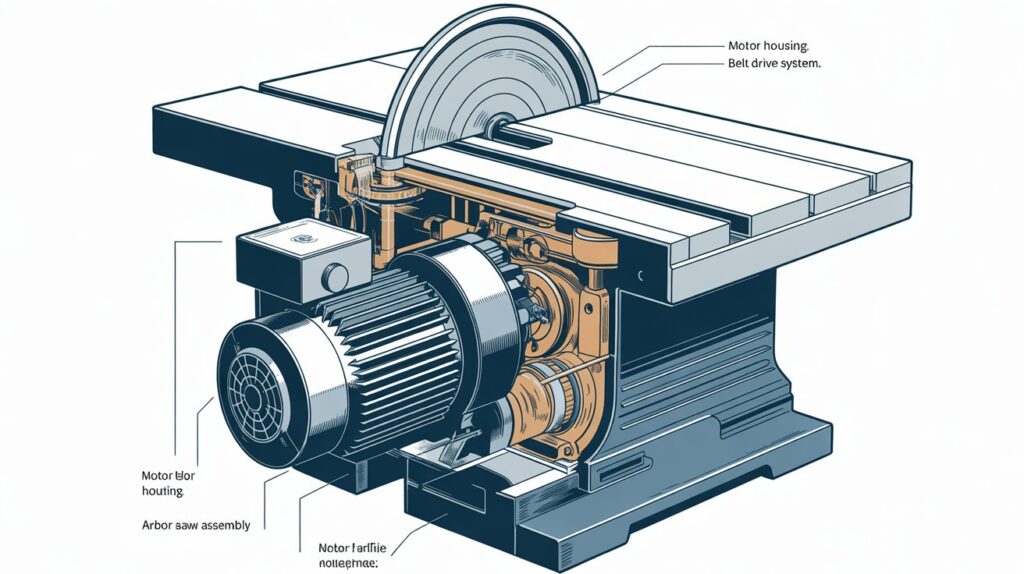

11. Drive Belt and Pulleys

The drive belt and pulleys are essential table saw components in belt-driven saws, transferring power from the table saw motor and arbor to the blade for smooth and consistent cutting. These table saw parts help maintain proper blade alignment and calibration and reduce vibration, which directly improves cutting precision. Well-maintained belts and pulleys support kickback prevention and enhance overall workshop safety, making them a crucial element of reliable woodworking tools and efficient wood cutting equipment.

12. Blade Height Adjustment Wheel

The blade height adjustment wheel is a key table saw component that allows users to raise or lower the saw blade for precise cutting depth. As an essential table saw part, it works with proper saw blade adjustment to maintain accurate blade alignment and calibration, directly improving cutting precision. Correct use of the adjustment wheel also supports kickback prevention and enhances workshop safety, making it a vital control for professional woodworking tools and effective wood cutting equipment.

13. Blade Tilt Adjustment Mechanism

The blade tilt adjustment mechanism is an important table saw component that allows the saw blade to tilt for bevel and angled cuts. As a precise table saw part, it works with saw blade adjustment and blade alignment and calibration to ensure accurate cutting precision. Proper use of this mechanism supports kickback prevention and improves workshop safety, making it a crucial feature for professional woodworking tools and versatile wood cutting equipment.

Safety Table Saw Components

14. Blade Guard

The blade guard is a vital table saw component designed to protect users from direct contact with the spinning blade while allowing visibility during cuts. As a key table saw part for workshop safety, it works alongside kickback prevention features to reduce accidents and injuries. Proper use of the blade guard ensures safe saw blade adjustment and supports accurate blade alignment and calibration, making it an essential feature for professional woodworking tools and reliable wood cutting equipment.

15. Riving Knife

The riving knife is a crucial table saw component that prevents the workpiece from pinching the blade, significantly reducing the risk of kickback. As an essential safety feature for table saws, it works with the blade guard and anti-kickback pawls to enhance operator protection and maintain cutting accuracy. Properly aligned, the riving knife supports smooth wood feed control and ensures consistent bevel and rip cuts, making it a key element for safe and efficient use of precision woodworking tools and professional wood cutting equipment.

16. Splitter

The splitter is an important table saw component that helps prevent the workpiece from closing behind the blade, reducing kickback risk during cutting. As a vital safety part for table saws, it works alongside the riving knife and blade guard to improve operator protection and maintain consistent cutting accuracy. By stabilizing the wood and supporting smooth material feed control, the splitter enhances precision woodworking tools performance and ensures safer operation of professional wood cutting equipment.

17. Anti-Kickback Pawls

The anti-kickback pawls are essential table saw components designed to prevent the workpiece from being thrown back toward the operator, enhancing workshop safety. As a key safety accessory for table saws, they work with the riving knife and splitter to ensure controlled wood feed and maintain precise cutting accuracy. Properly installed, anti-kickback pawls support smooth operation of professional woodworking tools and reliable wood cutting equipment, reducing the risk of accidents during both rip and crosscuts.

18. Power Switch and Emergency Stop

The power switch and emergency stop are critical table saw components that allow users to quickly control and shut off the saw, enhancing workshop safety. As essential control parts for table saws, they work with safety accessories like the blade guard and riving knife to prevent accidents and maintain reliable cutting operations. Proper use of these switches ensures smooth machine control, protects the operator during unexpected situations, and supports efficient operation of professional woodworking tools and durable wood cutting equipment.

Dust Management and Support Components

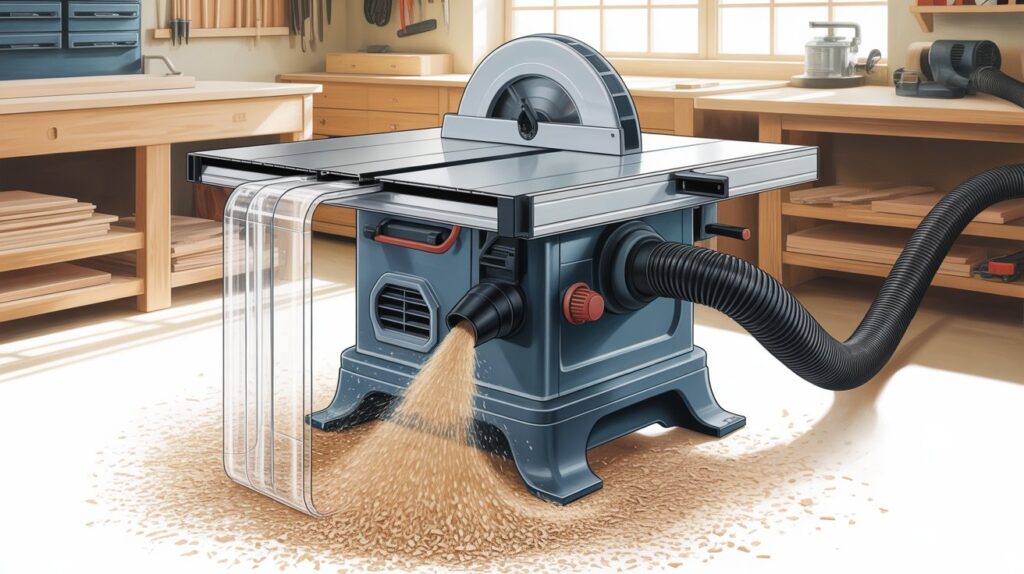

19. Dust Collection Port

The dust collection port is a vital table saw component that removes sawdust and debris from the cutting area, improving workshop cleanliness and operator safety. As an important dust management feature for table saws, it works with dust shrouds and table saw accessories to maintain clear visibility and prevent clogging, supporting consistent cutting precision. Proper use of the dust collection port enhances the efficiency of woodworking tools and keeps wood cutting equipment running smoothly while reducing airborne particles for a safer work environment.

20. Dust Shroud

The dust shroud is an important table saw component that surrounds the blade area to efficiently direct sawdust toward the dust collection port, keeping the workspace clean and safe. As a key dust management accessory for table saws, it improves cutting precision by maintaining visibility and preventing debris buildup near the blade. Proper use of the dust shroud enhances workshop safety, supports smooth material feed control, and ensures optimal performance of professional woodworking tools and reliable wood cutting equipment.

21. Stand or Base

The stand or base is a fundamental table saw component that provides stability and support for the entire saw, ensuring safe and precise operation. As a key structural part for table saws, it maintains proper blade alignment and calibration while reducing vibration, which improves cutting precision. A sturdy stand or base enhances workshop safety, supports smooth material handling, and is essential for reliable performance of professional woodworking tools and durable wood cutting equipment.

22. Cabinet (Cabinet Saws Only)

The cabinet is a key table saw component found on cabinet saws, providing an enclosed base that houses the motor and internal mechanisms for improved stability and durability. As an essential structural and dust management part for table saws, it supports accurate blade alignment and calibration and enhances cutting precision by reducing vibration. The cabinet also improves workshop safety by containing moving parts, facilitates efficient dust control, and ensures reliable performance of professional woodworking tools and heavy-duty wood cutting equipment.

23. Extension Wings

The extension wings are important table saw components that expand the tabletop surface, providing additional support for larger workpieces and improving overall cutting precision. As a valuable table saw accessory, they work with rip fence for table saw systems and miter gauge components to maintain straight and accurate cuts. Extension wings enhance material handling, support safer operation, and improve workshop efficiency, making them essential for professional woodworking tools and versatile wood cutting equipment.

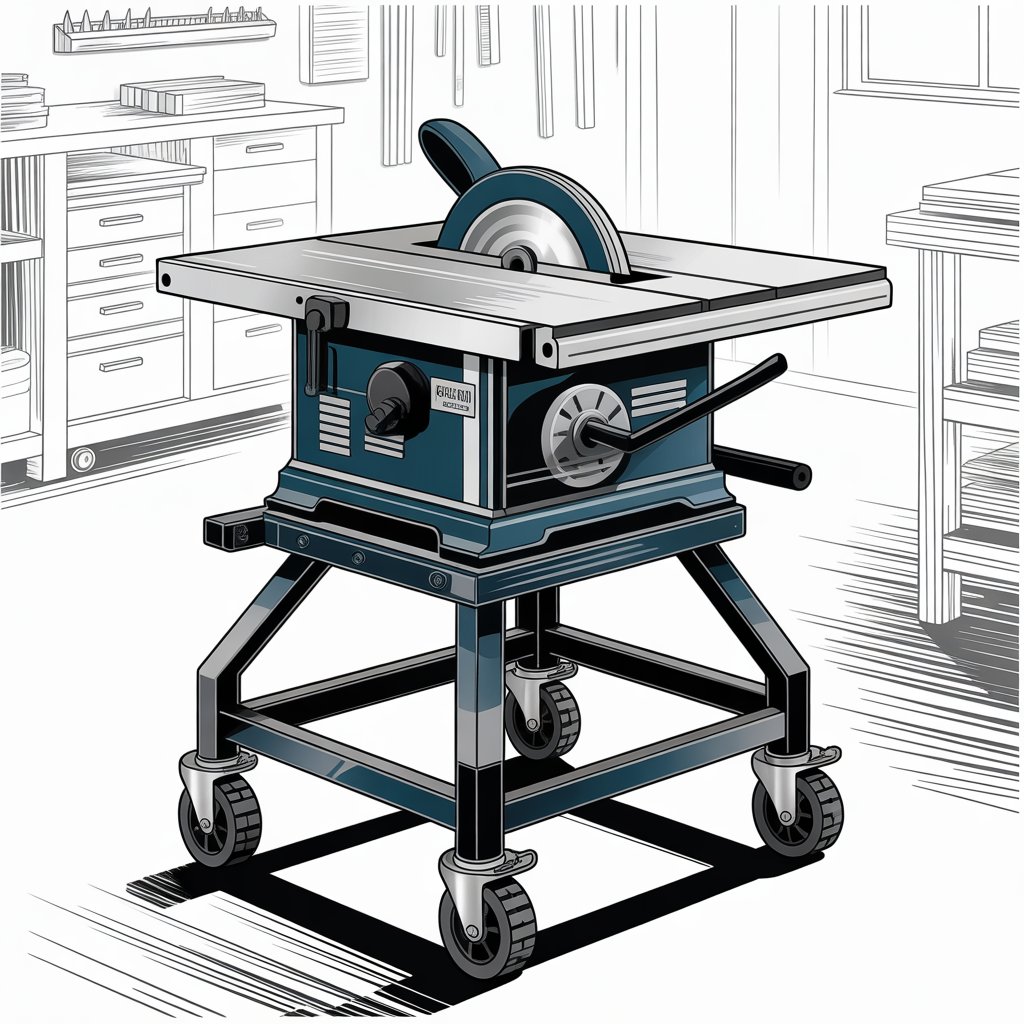

24. Mobile Base

The mobile base is a practical table saw component that allows users to easily move the saw within the workshop while maintaining stability during operation. As a key accessory for table saws, it supports proper blade alignment and calibration and helps maintain cutting precision by keeping the saw level on uneven surfaces. The mobile base improves workshop efficiency, enhances material handling, and ensures safer use of professional woodworking tools and versatile wood cutting equipment, especially in compact or multi-use workspaces.

Accessories That Enhance Table Saw Performance

25. Zero-Clearance Inserts

The zero-clearance inserts are essential table saw components that reduce tear-out and support cleaner, more precise cuts by minimizing the gap around the blade. As a specialized table saw accessory, they enhance cutting precision and help maintain proper blade alignment and calibration. These inserts improve workshop safety by stabilizing the workpiece, support efficient material handling, and increase the performance of professional woodworking tools and advanced wood cutting equipment.

26. Push Stick and Push Block

The push stick and push block are vital table saw components designed to keep the operator’s hands safely away from the blade while guiding the workpiece through cuts. As essential safety accessories for table saws, they enhance workshop safety and support precise material feed control, improving overall cutting precision. Proper use of push sticks and push blocks helps prevent kickback, maintains accurate blade alignment and calibration, and ensures safer operation of professional woodworking tools and reliable wood cutting equipment.

Conclusion

Understanding table saw components is essential for achieving accurate cuts, maintaining safety, and maximizing the lifespan of your tool. Each part, from the blade and arbor to safety features like the riving knife and push sticks, works together to deliver precision and control. By knowing how these components function and how to maintain them, woodworkers can improve cutting precision, prevent accidents, and make the most of their woodworking tools and wood cutting equipment. Mastery of these components ensures efficient, safe, and professional woodworking evry time.

Top 05 FAQs

1. What are the main table saw components and their functions?

The main table saw components include the blade, arbor, rip fence, miter gauge, blade guard, riving knife, motor, and dust collection system. Each part works together to ensure cutting precision, safe operation, and efficient use of woodworking tools and wood cutting equipment.

2. How do I maintain table saw components for optimal performance?

Regular maintenance of table saw components includes cleaning the tabletop, checking blade alignment and calibration, inspecting the arbor and belts, and lubricating moving parts. Proper care improves cutting precision, prevents kickback, and extends the life of your professional woodworking tools.

3. What safety features are included in table saw components?

Key safety-focused table saw components include the blade guard, riving knife, splitter, anti-kickback pawls, and push sticks. These parts work together to reduce the risk of kickback, protect the operator, and ensure safer use of wood cutting equipment.

4. What is the purpose of the rip fence and miter gauge in table saw components?

The rip fence and miter gauge are essential table saw components that guide the workpiece during rip cuts and crosscuts. They help maintain accurate measurements, improve cutting precision, and allow safer, controlled material handling when using woodworking tools.

5. How does the dust collection system improve table saw performance?

The dust collection system, including the dust collection port and dust shroud, is a vital table saw component that removes sawdust from the cutting area. It enhances workshop safety, maintains clear visibility for cutting precision, and keeps wood cutting equipment running efficiently.